3 in 1 Laser Welding Parameters Setup

Operation Tips:

① The thicker the plate, the thicker the welding wire; the bigger the power, and the slower the wire feeding speed

② The less the power, the whiter the welding surface. The bigger the power, the weld seam will change from color to black, and the single-sided form will be formed at this time.

③ The welding wire should not be thicker than the plate thickness but closing to the plate thickness. The welding wire will also affect the fullness of the weld.

④ The thinner the weld wire, the less the scanning width.

Our Testing on Different Materials

Affected by different brands of lasers, the following processes use the following laser to do proofing tests. But it is for reference only, and need to be fine-tuned appropriately when using.

①Reci / Max / JPT

②Argon

- Carbon steel/galvanized sheet

|

Material |

Thickness(MM) |

Scanning Speed |

Scanning Width |

Power |

Wire No. |

Welding Angle |

Welding Effect |

Wire Feeding Speed |

|

Carbon Steel |

1 |

400 |

2.5 |

380 |

ER1.0 |

Flat Fillet Welding |

90% Penetration |

80 |

|

Carbon Steel |

1 |

400 |

2.5 |

380 |

ER1.0 |

Inner Corner Welding |

yellow |

80 |

|

Carbon Steel |

1 |

400 |

2.5 |

380 |

ER1.0 |

Outer Corner Welding |

70% Penetration |

90 |

|

Carbon Steel |

0.5 |

400 |

2.5 |

220 |

ER0.8 |

Flat Fillet Welding |

Penetration |

100 |

|

Carbon Steel |

0.5 |

400 |

2.5 |

220 |

ER0.8 |

Inner Corner Welding |

yellow |

100 |

|

Carbon Steel |

0.5 |

400 |

2.5 |

220 |

ER0.8 |

Outer Corner Welding |

Penetration |

100 |

|

Carbon Steel |

2 |

400 |

3 |

700 |

ER1.2 |

Flat Fillet Welding |

100% full penetration |

70 |

|

Carbon Steel |

2 |

400 |

3 |

700 |

ER1.2 |

Inner Corner Welding |

White |

70 |

|

Carbon Steel |

2 |

400 |

3 |

700 |

ER1.2 |

Outer Corner Welding |

100% full penetration |

60 |

|

Carbon Steel |

3 |

400 |

3 |

1200 |

ER1.2 |

Flat Fillet Welding |

100% full penetration |

65 |

|

Carbon Steel |

3 |

400 |

3 |

1200 |

ER1.2 |

Inner Corner Welding |

White |

75 |

|

Carbon Steel |

3 |

400 |

3 |

1200 |

ER1.2 |

Outer Corner Welding |

80% penetration |

60 |

|

Carbon Steel |

4 |

400 |

3.5 |

1500 |

ER1.6 |

Flat Fillet Welding |

100% full penetration |

60 |

|

Carbon Steel |

4 |

400 |

3.5 |

1500 |

ER1.6 |

Inner Corner Welding |

100% full penetration |

60 |

|

Carbon Steel |

4 |

400 |

3.5 |

1500 |

ER1.6 |

Outer Corner Welding |

80% penetration |

60 |

|

Carbon Steel |

5 |

400 |

3.5 |

1700 |

ER1.6 |

Flat Fillet Welding |

100% full penetration |

60 |

|

Carbon Steel |

5 |

400 |

3.5 |

1700 |

ER1.6 |

Inner Corner Welding |

100% full penetration |

60 |

|

Carbon Steel |

5 |

400 |

3.5 |

1700 |

ER1.6 |

Outer Corner Welding |

80% penetration |

60 |

|

Carbon Steel |

6 |

400 |

4 |

2000 |

ER1.6 |

Flat Fillet Welding |

80% penetration |

60 |

|

Carbon Steel |

6 |

400 |

4 |

2000 |

ER1.6 |

Inner Corner Welding |

60% penetration |

60 |

|

Carbon Steel |

6 |

400 |

4 |

2000 |

ER1.6 |

Outer Corner Welding |

80% penetration |

60 |

|

Carbon Steel |

6 |

400 |

3.5 |

2200 |

ER1.6 |

Flat Fillet Welding |

100% full penetration |

60 |

|

Carbon Steel |

6 |

400 |

3.5 |

2500 |

ER1.6 |

Inner Corner Welding |

100% full penetration |

60 |

|

Carbon Steel |

7 |

400 |

3 |

2600 |

ER1.6 |

Flat Fillet Welding |

100% full penetration |

50 |

|

Carbon Steel |

7 |

400 |

3 |

2800 |

ER1.6 |

Inner Corner Welding |

100% full penetration |

50 |

|

Carbon Steel |

8 |

400 |

3 |

3000 |

ER1.6 |

Flat Fillet Welding |

100% full penetration |

45 |

|

Carbon Steel |

8 |

400 |

3 |

3000 |

ER1.6 |

Inner Corner Welding |

100% full penetration |

45 |

Note: Affected by the zinc layer of the galvanized sheet, the power can be appropriately reduced when welding galvanized sheet.

- stainless steel

|

Material |

Thickness(MM) |

Scanning Speed |

Scanning Width |

Power |

Wire No. |

Welding Angle |

Welding Effect |

|

Stainless Steel |

1 |

400 |

2.5 |

200 |

ER304 1.0 |

|

White |

|

Stainless Steel |

1 |

400 |

2.5 |

320 |

ER304 1.0 |

|

Colorful |

|

Stainless Steel |

1 |

400 |

2.5 |

350 |

ER304 1.0 |

|

Colorful |

|

Stainless Steel |

2 |

400 |

2.5 |

600 |

ER304 1.0 |

Flat Fillet Welding |

Penetration |

|

Stainless Steel |

2 |

400 |

2.5 |

450 |

ER304 1.0 |

Flat Fillet Welding |

Blue with White |

|

Stainless Steel |

2 |

400 |

2.5 |

260 |

ER304 1.0 |

Inner Corner Welding |

Gold |

|

Stainless Steel |

2 |

400 |

2.5 |

200 |

ER304 1.0 |

Flat Fillet Welding |

Yellow |

|

Stainless Steel |

3 |

400 |

3 |

550 |

ER304 1.2 |

Flat Fillet Welding |

Colorful |

|

Stainless Steel |

3 |

400 |

3 |

700 |

ER304 1.2 |

Inner Corner Welding |

70% Penetration |

|

Stainless Steel |

3 |

400 |

3 |

800 |

ER304 1.2 |

Flat Fillet Welding |

Single-side Formed |

|

Stainless Steel |

4 |

400 |

3 |

1000 |

ER304 1.2 |

Flat Fillet Welding |

Colorful |

|

Stainless Steel |

4 |

400 |

3 |

1200 |

ER304 1.2 |

Inner Corner Welding |

70% Penetration |

|

Stainless Steel |

4 |

400 |

3 |

1500 |

ER304 1.2 |

Flat Fillet Welding |

Single-side Formed |

|

Stainless Steel |

5 |

400 |

3 |

1500 |

ER304 1.6 |

Inner Corner Welding |

Colorful |

|

Stainless Steel |

5 |

400 |

3 |

1500 |

ER304 1.6 |

Flat Fillet Welding |

50% Penetration |

|

Stainless Steel |

5 |

400 |

3 |

1700 |

ER304 1.6 |

Outer Corner Welding |

80% Penetration |

|

Stainless Steel |

6 |

400 |

3 |

1500 |

ER304 1.6 |

Flat Fillet Welding |

50% Penetration |

|

Stainless Steel |

6 |

400 |

4 |

1700 |

ER304 1.6 |

Outer Corner Welding |

Penetration |

|

Stainless Steel |

6 |

400 |

5 |

1900 |

ER304 1.6 |

Inner Corner Welding |

90% Penetration |

Note: 3000W welding stainless steel refers to carbon steel table form.

III. aluminium

The aluminum parameters refer to stainless steel parameters. The power can only be increased by 20%-30%. What’s more, there are also differences on the focus, which need to be adjusted manually.

Case 1: 0.5MM stainless steel internal corner welding

Test 1:

Feeding 0.8mm stainless steel wire

Scanning speed 350

Scanning width 2

Peak power 350

Duty cycle 100

Frequency 2000

The plate is penetrated, and big deformation, so we reduce the power.

Test 2:

Feeding 0.8mm stainless steel wire

Scanning speed 350

Scanning width 2

Peak power 260

Duty cycle 100

Frequency 2000

The deformation has been reduced, but it is still easy to be burnt when the laser starts flowing out, that’s the reason why we continue to reduce the power.

Test 3:

Feeding 0.8mm stainless steel wire

Scanning speed 350

Scanning width 2

Peak power 200

Duty cycle 100

Frequency 2000

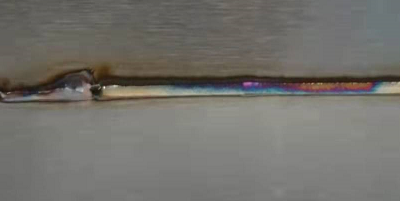

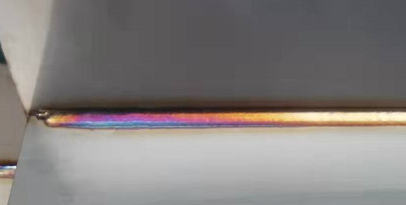

The welding effect is as follows ①. When you increase the width to 3 is as it shown in figure ②.

①

②