Service

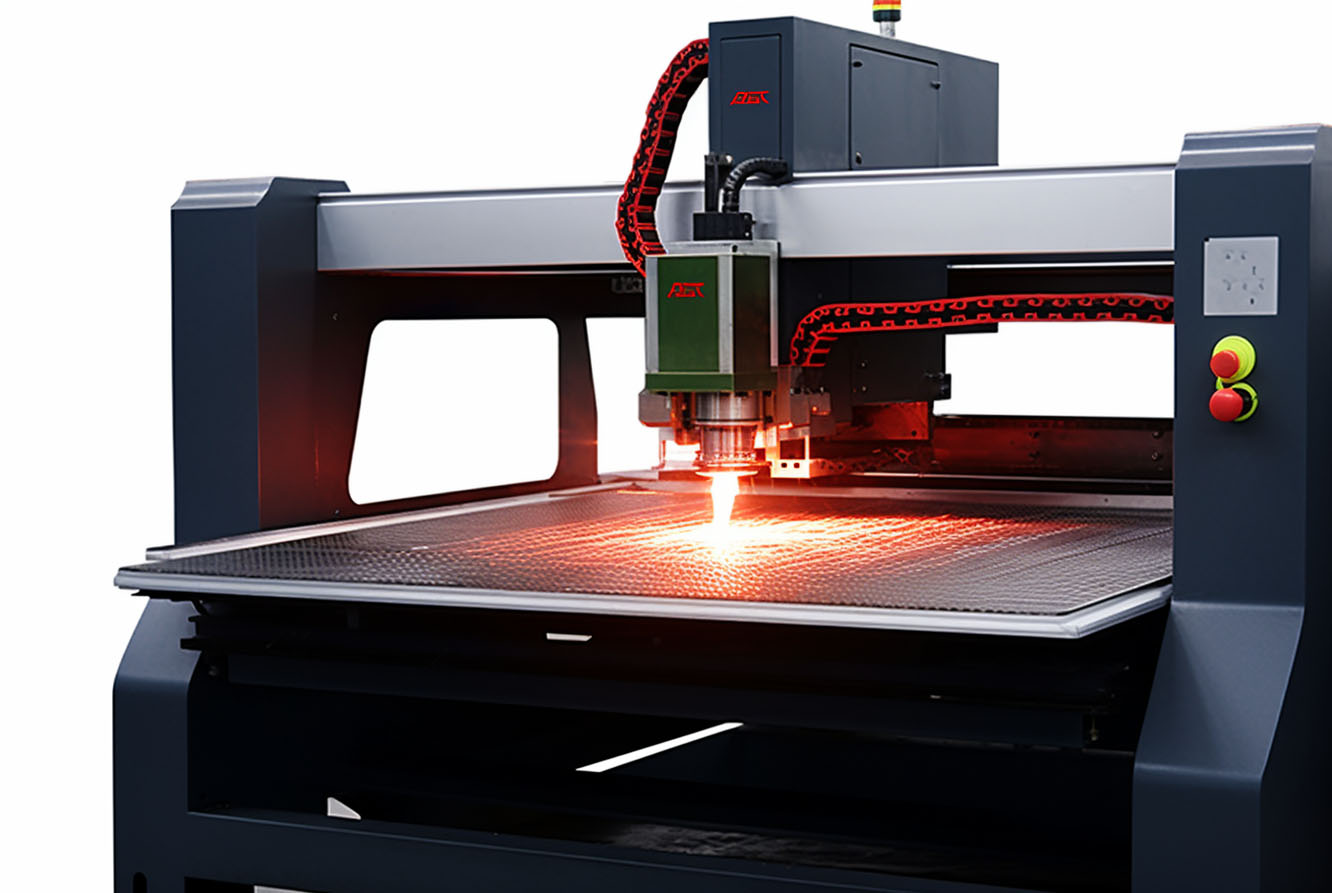

A Fiber Metal Laser Cutting Machine is a sophisticated device used for cutting various types of metals, such as steel, aluminum, brass, and copper, using a high-intensity laser. The process involves directing the laser beam through a nozzle to the metal surface, which melts, burns, or vaporizes the material, resulting in a high-quality finish.

These machines are known for their precision, speed, and efficiency in cutting metal materials. They offer several advantages over traditional metal cutting methods, including:

- High Precision and Accuracy: The laser beam is focused on a small area, allowing for precise cuts with smooth edges.

- Complex Cutting Capabilities: They can easily handle intricate designs and patterns, which are difficult to achieve with conventional cutting methods.

- Fast Processing Speed: Laser cutting is much faster than traditional methods, significantly reducing processing time.

- Low Heat Affect Zone: The laser’s focused energy minimizes the heat-affected zone, reducing material distortion and warping.

- Minimal Material Wastage: The precision and control of the laser beam result in minimal material wastage.

- Versatility: Fiber metal laser cutters can work with a variety of metal thicknesses and types.

Main Features

Fiber Metal Laser Cutting Machines stand out in the industrial cutting sector due to their advanced technology and efficiency. Here are the main features that make them highly sought-after:

-

High Precision Cutting: These machines offer exceptional precision in cutting, with the ability to produce intricate designs and maintain exact tolerances. The laser beam is focused to a fine point, allowing for detailed cuts without the material deformation that can occur with more traditional cutting methods.

-

Fast Cutting Speed: One of the most significant advantages of fiber laser cutters is their speed. They can cut through metal at rates far quicker than mechanical cutting methods. This speed does not sacrifice quality; even at high speeds, the cuts are clean and precise.

-

Versatile Cutting Capabilities: Fiber lasers are incredibly versatile and can cut a wide range of metals, including steel, aluminum, copper, and brass. They can handle various material thicknesses and are capable of executing complex cuts and intricate designs that would be challenging or impossible with traditional cutting methods.

-

Low Maintenance: Unlike other types of laser cutters (like CO2 lasers), fiber lasers have fewer moving parts and require less maintenance. This feature results in lower operational costs over time and minimizes downtime due to maintenance or repairs. The solid-state design of the laser source also contributes to its robustness and longevity.

These features make fiber metal laser cutting machines highly desirable for industries that require precise, efficient, and versatile metal cutting solutions, such as aerospace, automotive, electronics, and machinery manufacturing. The combination of speed, precision, versatility, and low maintenance makes them an excellent investment for businesses looking to improve their production capabilities and efficiency.

Sub Topics

Sure, let’s delve into the subtopics related to Fiber Metal Laser Cutting Machines:

Working Principle

-

Fiber Laser Generation: The process starts with the creation of a laser beam, which is generated in the fiber laser source. This involves stimulating a doped fiber optic with diode lasers, leading to the emission of a high-intensity laser beam.

-

Beam Delivery System: The generated laser beam is delivered to the cutting head through a series of mirrors and a fiber optic cable. This system ensures that the beam remains focused and stable during its journey from the source to the material surface.

-

Material Interaction: When the laser beam reaches the material, it heats, melts, and vaporizes the metal. The cutting process is precise and is controlled by moving the laser beam or workpiece, resulting in highly accurate cuts.

Applications

-

Steel Fabrication: Fiber lasers are extensively used in cutting, drilling, and marking steel for construction, manufacturing, and engineering applications.

-

Automotive Industry: In the automotive sector, they’re used for cutting complex components, ensuring precision and strength in vehicle parts.

-

Aerospace Industry: Aerospace applications include cutting and shaping aircraft components, where precision and weight reduction are critical.

Advantages

-

Superior Cutting Quality: These machines offer unmatched cutting quality with smooth edges and precise dimensions.

-

High Efficiency: Their fast cutting speeds and ability to handle various materials efficiently make them highly productive.

-

Cost-effective: With low maintenance needs and efficient use of energy, they are a cost-effective solution for metal cutting.

Components

-

Laser Source: The core component where the laser beam is generated.

-

Cutting Head: This includes the focusing lens and nozzle, and it directs the laser beam onto the material.

-

Control System: A sophisticated software interface that controls the cutting process, including the movement of the cutting head and the laser parameters.

-

Cooling System: Essential for maintaining the optimal temperature of the laser source and other components.

Safety Measures

-

Protective Enclosure: A shield around the cutting area to protect the operator from direct exposure to the laser beam.

-

Beam Safety Interlocks: These prevent the laser from operating when the protective enclosure is not in place.

-

Emergency Stop Button: Allows for immediate shutdown of the machine in case of an emergency.

Maintenance

-

Regular Lens Cleaning: Ensuring the lens is clean for optimal cutting performance.

-

Calibration of Cutting Parameters: Regular calibration to maintain precision in cutting.

-

Periodic Machine Inspection: Regular inspections of mechanical and optical components to ensure everything is functioning correctly.

These subtopics cover the broad spectrum of the technology, applications, benefits, components, safety, and maintenance aspects of Fiber Metal Laser Cutting Machines, highlighting their complexity and versatility in modern manufacturing and fabrication processes.