Meet Precision and Efficiency: Best Fabric Laser Cutting Machine

As the textile industry continues to evolve, fabric laser cutting machine stands as a testament to innovation, efficiency, and sustainability. Embracing this technology can lead to higher-quality products, reduced waste, and ultimately, a more competitive edge in the market. Precision Fabric Cutting Made Easy with Wuhan BST LASER Machinery’s Cutting-Edge Laser Machine!

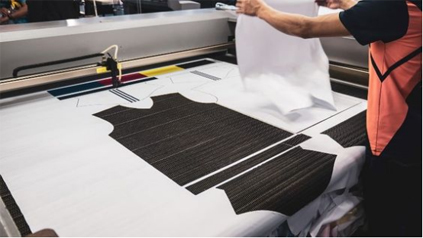

In the world of textile manufacturing, precision, speed, and quality are paramount. This is where fabric laser cutting machines come into play, revolutionizing the industry by providing a highly efficient and accurate means of cutting fabrics. In this blog, we will explore the various facets of fabric laser cutting machines, from their manufacturers to safety measures and the economic aspects of investing in one.

Best Fabric Laser Cutting Machine Manufacturer: Wuhan BST LASER Machinery Co., Ltd

Wuhan BST LASER Machinery’s Fabric Laser Cutting Machine: Your Solution for Flawless Fabrication! When it comes to fabric laser cutting machines, one name that stands out is Wuhan BST LASER Machinery Co., Ltd. This reputable manufacturer has established itself as a leading player in the industry, known for producing cutting-edge equipment that caters to the evolving needs of textile manufacturers. With a commitment to innovation and quality, Wuhan BST LASER Machinery Co., Ltd has gained the trust of businesses worldwide.

High-Quality Fabric Laser Cutting Machine: Ensuring Safety in Fabric Laser Cutting

Operating fabric laser cutting machines requires strict adherence to safety protocols. Laser radiation and the fumes generated during the cutting process can pose significant health risks to workers if not properly managed. To mitigate these risks, fabric laser cutting machines are equipped with essential safety features.

- Exhaust Systems:These machines are typically fitted with high-performance exhaust systems that efficiently remove fumes and particles generated during cutting. Proper ventilation is crucial in maintaining a safe working environment.

- Safety Interlocks:To prevent accidents, fabric laser cutting machines are often equipped with safety interlocks that halt the cutting process if the machine’s enclosure is opened during operation. This feature ensures that operators are protected from direct laser exposure.

High-Performance Fabric Laser Cutting Machine: The Importance of Maintenance

Like any industrial equipment, fabric laser cutting machine requires regular maintenance to perform at their best. Maintenance routines not only extend the machine’s lifespan but also ensure consistent cutting quality.

- Cleaning the Lens: The laser cutting process can deposit residue on the lens, reducing cutting accuracy. Regular cleaning of the lens is essential to maintain optimal performance.

- Laser Calibration: Laser calibration is crucial for achieving precise cuts. Periodic checks and calibrations help ensure that the laser beam remains focused and accurate.

- Component Inspection:Routine inspection of various components such as mirrors, rails, and belts is necessary to identify and address any wear or damage promptly.

Best Fabric Laser Cutting Machine: Counting the Costs and Benefits

Investing in a fabric laser cutting machine can be a significant financial decision, but it offers a range of benefits that can justify the expenditure.

- Increased Productivity: Fabric laser cutting machines are incredibly fast and accurate, significantly reducing the time required for cutting compared to traditional methods. This increase in productivity can lead to substantial cost savings in labor and time.

- Reduced Labor Costs:With automation at the core of fabric laser cutting machines, businesses can reduce their reliance on manual labor, leading to lower labor costs in the long run.

- Improved Quality: Laser cutting offers unmatched precision, resulting in consistently high-quality cuts. This not only enhances product quality but also reduces material wastage.

High-Quality Fabric Laser Cutting Machine — Minimal Material Waste: A Sustainable Approach to Cutting

When it comes to fabric cutting, minimizing material waste is paramount, not only for cost-effectiveness but also for sustainability. Fabric laser cutting machines, like those manufactured by Wuhan BST LASER Machinery Co., Ltd, excel in this regard. They operate with remarkable precision, following the programmed path to cut fabric with the utmost accuracy. This precision means there’s little to no need for additional trimming or adjustments, significantly reducing material waste.

Traditional cutting methods often lead to irregular edges and leftover scraps, which can accumulate into significant waste over time. In contrast, fabric laser cutting machines optimize material usage, making them a sustainable choice for textile manufacturers.

High-Performance Fabric Laser Cutting Machine — Non-Contact Cutting: Preserving Fabric Integrity

One of the standout features of fabric laser cutting machines is their non-contact cutting process. In this method, there is no physical contact between the cutting tool and the fabric. This eliminates the risk of fabric distortion or damage during cutting.

Traditional cutting tools, such as rotary blades or die-cutting machines, can cause friction and drag on the fabric, potentially leading to stretching, warping, or fraying. Fabric laser cutting, on the other hand, produces clean and precise cuts without any adverse effects on the material. This is particularly crucial when working with delicate or high-value fabrics, ensuring that the fabric’s integrity remains intact.

Best Fabric Laser Cutting Machine — Scalability: Tailored to Your Production Needs

Fabric laser cutting machines are incredibly versatile and adaptable to various production scales. Whether you’re a small-scale manufacturer or an industrial giant, there’s a fabric laser cutting machine configuration that suits your needs.

Wuhan BST LASER Machinery Co., Ltd offers a range of sizes and configurations to cater to different production requirements. Small-scale operations can benefit from compact and affordable models, while large-scale manufacturers can opt for high-speed and high-power machines to meet their demands. This scalability ensures that fabric laser cutting technology is accessible and advantageous for businesses of all sizes.

Conclusion

Fabric laser cutting machine, exemplified by manufacturers like Wuhan BST LASER Machinery Co., Ltd, have revolutionized the textile industry. Explore Wuhan BST LASER Machinery’s Fabric Laser Cutting Machine – Delivering Quality and Efficiency! By prioritizing safety, and maintenance, and considering the long-term cost benefits, businesses can harness the power of these machines to stay competitive in the ever-evolving world of textiles. Investing in fabric laser cutting technology isn’t just a smart move; it’s a strategic one that can lead to increased efficiency, improved product quality, and a stronger bottom line.