1500W 2000W Cantilever Mold Repair Fiber Laser Welding Machine

|

Category |

|

|

Model No. |

BE-WF1500M |

|

Views |

58700 |

|

Rating |

⭐⭐⭐⭐⭐ |

|

Price Range |

US$4,999-US$11,999/Set |

|

Payment Term |

T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

|

Production Time |

7-15 Days |

|

Shipping |

Air/Sea/Train/Truck |

|

Warranty Period |

Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

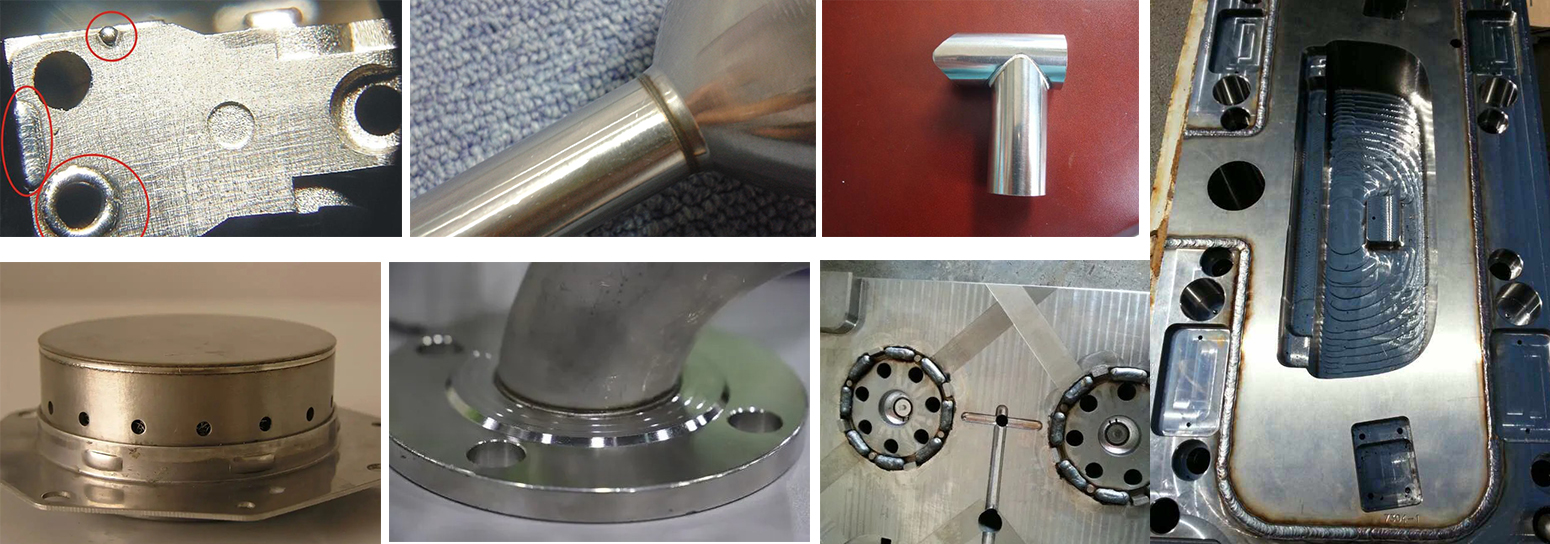

Cantilever mold fiber laser welding machine can repair of all metal parts molds, which makes up for the shortcomings of the traditional welding technology in repairing the fine surface of welding. Heat affected zone is small and post-treatment are avoided, which greatly saves the production cycle of the mold.

|

Comparison of Fiber Mold Laser Welding Machine and YAG Mold Laser Welding Machine |

||

|

Item |

Fiber Laser Welding Machine |

YAG Laser Welding Machine |

|

Power |

1000w/1500w/2000w/3000w |

300w/400w/600w |

|

Welding Material |

Stainless Steel/Carbon Steel/Mild Steel/Aluminum/Galvanized Sheet/Iron/Brass |

Stainless Steel/Carbon Steel/Mild Steel/Galvanized Sheet/Iron |

|

Welding Thickness |

0-4MM(single side welding) |

0-2mm(single side welding) |

|

Laser Source |

* optic fiber laser source |

* YAG laser module and Xenon lamp |

|

Welding Mode |

* continuous welding, no raised spot, |

* spot welding, fish-scale welding pattern. |

|

Cooling |

Built-in water cooling |

Separate water cooling |

|

Laser Path |

Fiber Laser Welding Machine (Continuous welding mode ) |

YAG laser welding machine (intermittent mode) ,use Nd3+: YAG pulse laser source,there has many optional laser parts like xenon lamp,laser cavity,many lens,etc |

|

Laser Head |

Industrial Laser welding head with QBH connector |

Normal Laser Welding Head |

|

Welding Speed |

* Fastest speed of all welding machines, high efficiency, saving 2-3 manpower. |

* Faster speed than argon arc welding. |

|

Operation |

* Very easy operation, no need much skills, no need adjust laser path, free of maintenance, as easy as using mobile phone. |

* Common use. Operators can use well under our instructions. It needs adjust laser path. |

Good Features

* Cantilever design, suitable for all big, medium and small molds.Especially suitable for heavy unremovable molds.

* The laser head and laser path can rotate 360 degree and laser head lift up down which is more flexible for welding different position of molds.

* Adopting fiber laser source, small heat affected zone, and small deformation.

* The automatic shading system avoid eye irritation during working.

* The table is electrically up down, equipped with ball screw and linear guide rail, which is light and flexible, accurate positioning.

* Electric adjustment of light spot size.

Parts Introduction

Fiber Laser Source

Adopt fiber laser source, modurised design, no need adjust laser path, free of maintenance, lifetime over 10 years and brings great convenience.

Water Chiller

Integrated design, and cooling the fiber laser source to ensure machine long time working well. Double temperature display and operator can observe the working status easily.

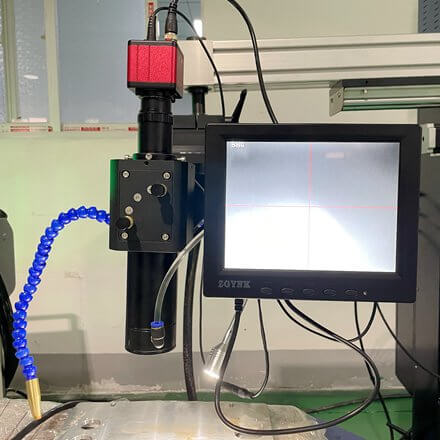

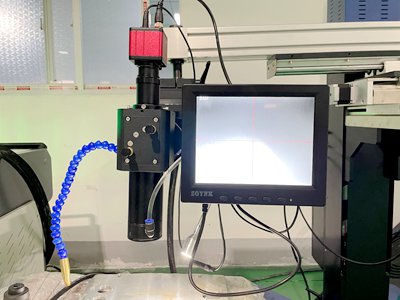

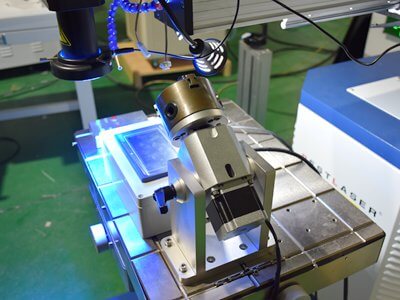

CCD Camera+High Resolution Screen

It can position the welding spot precisely. Operator can observe the welding details clearly on the screen.

Controller

The cantilever can move left/right/forward/backward/up/down easily by pressing the joystick and buttons.

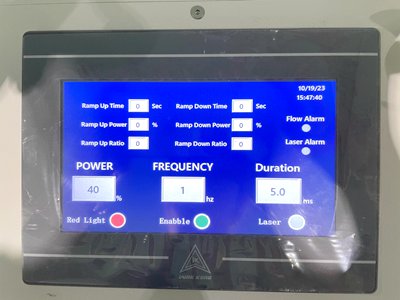

Software Screen

Self-designed software screen, easy operation and powerful functions. Parameters will be setup well in our factory and brings convenience.

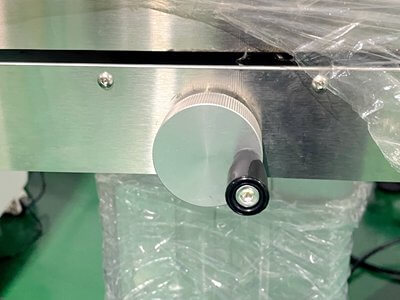

Rotating Knobs

Move working table left/right/forward/backward by rotating knobs.

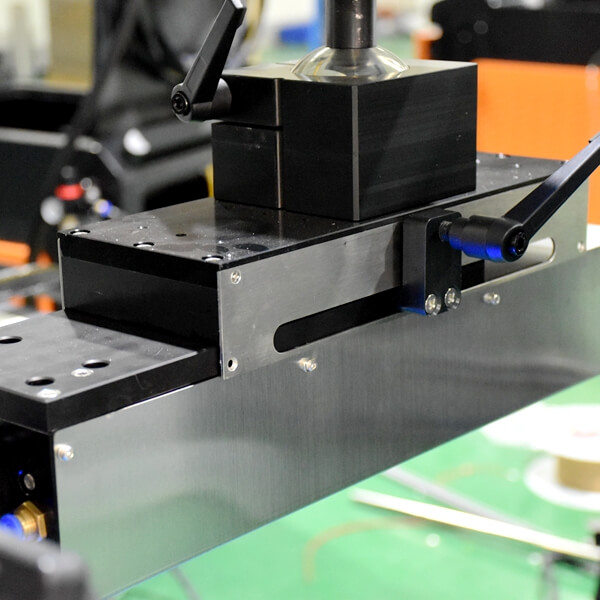

XY Electric Table

Cantilever arm movement controlled by the electric table. High precision moving and positioning.

Lock

Loosen the lock, the X axis can move lef/right. The travelling distance extended, and easy for big molds welding.

Rotary Device

Round objects, such as round heaters, and tubing, can be worked on by the machine thanks to its rotational device, which has an 80mm diameter.

It is powered by a step motor and outperforms manual labor.

Application

Gold,Silver,Stainless Steel,Copper,Aluminum,Chrome Brass,etc; Alloy and metal oxides: Anodized Aluminum; mobile phones, digital products, automobile and motorcycle and other mould making and mould industries.

|

Mode |

BE-WF1500M |

BE-WF2000M |

|

|

Laser type |

fiber laser |

||

|

Laser power |

1500W |

2000W |

|

|

Laser wavelength |

1064~1080nm |

||

|

Power regulation range |

1~100% |

||

|

Frequency adjustment range |

1~100Hz |

||

|

Range of pulse width adjustment |

1~10ms |

||

|

Spot adjustment range |

0.1~3mm |

||

|

Output focal length |

150mm |

||

|

Maximum penetration |

≦3mm |

≦4mm |

|

|

Fuse welding wire |

Φ0.3~1.2mm |

Φ0.3~1.6mm |

|

|

Power supply demand |

220V 50~60Hz |

||

|

Electric stroke |

X/Y axis:100mm、Lifting z-axis:600mm, The cantilever base can rotate 360 degrees horizontally |

||

|

Cantilever size |

L800*W800*1600mm,Arm length1300mm |

||

|

Distance between welding joint and ground |

The highest 1150mm,lowest 400mm |

||

|

Positioning system |

Red light visual localization、CCD pass monitoring system |

||

|

Control panel |

Touch control operation |

||

|

Outgoing light control mode |

Foot control out light |

||

|

Cantilever control |

Electric remote control |

||

|

Cooling mode |

Water cooling |

||

|

Environmental requirements |

temperature 5~30℃;humidity 5~85% |

||

|

Size of main control cabinet |

L1080*W620*H1000 (mm) |

||

|

Welding table size |

L620* W 468* H691 (mm) |

||

|

Total weight of equipment |

400KG |

||

|

1000w Fiber Handheld Maximum Welding Depth |

||||||||

|

Thickness |

1mm |

2mm |

3mm |

4mm |

5mm |

6mm |

8mm |

10mm |

|

Stainless Steel |

● |

● |

● |

● |

|

|

|

|

|

Galvanized Sheet |

● |

● |

● |

|

|

|

|

|

|

Iron |

● |

● |

● |

● |

● |

|

|

|

|

Mild Steel |

● |

● |

● |

● |

● |

|

|

|

|

Aluminum |

● |

● |

|

|

|

|

|

|

|

Brass |

● |

● |

|

|

|

|

|

|

|

1000w Fiber Handheld Welding Penetration Thickness |

||||||||

|

Thickness |

1mm |

2mm |

3mm |

4mm |

5mm |

6mm |

8mm |

10mm |

|

Stainless Steel |

● |

● |

● |

|

|

|

|

|

|

Galvanized Sheet |

● |

● |

|

|

|

|

|

|

|

Iron |

● |

● |

● |

|

|

|

|

|

|

Mild Steel |

● |

● |

● |

|

|

|

|

|

|

Aluminum |

● |

|

|

|

|

|

|

|

|

Brass |

● |

|

|

|

|

|

|

|

|

1500w Fiber Handheld Maximum Welding Depth |

||||||||

|

Thickness |

1mm |

2mm |

3mm |

4mm |

5mm |

6mm |

8mm |

10mm |

|

Stainless Steel |

● |

● |

● |

● |

● |

|

|

|

|

Galvanized Sheet |

● |

● |

● |

● |

● |

|

|

|

|

Iron |

● |

● |

● |

● |

● |

|

|

|

|

Mild Steel |

● |

● |

● |

● |

● |

|

|

|

|

Aluminum |

● |

● |

● |

|

|

|

|

|

|

Brass |

● |

● |

|

|

|

|

|

|

|

1500w Fiber Handheld Welding Penetration Thickness |

||||||||

|

Thickness |

1mm |

2mm |

3mm |

4mm |

5mm |

6mm |

8mm |

10mm |

|

Stainless Steel |

● |

● |

● |

● |

|

|

|

|

|

Galvanized Sheet |

● |

● |

● |

|

|

|

|

|

|

Iron |

● |

● |

● |

● |

|

|

|

|

|

Mild Steel |

● |

● |

● |

● |

|

|

|

|

|

Aluminum |

● |

● |

|

|

|

|

|

|

|

Brass |

● |

● |

|

|

|

|

|

|

|

2000w Fiber Handheld Maximum Welding Depth |

||||||||

|

Thickness |

1mm |

2mm |

3mm |

4mm |

5mm |

6mm |

8mm |

10mm |

|

Stainless Steel |

● |

● |

● |

● |

● |

● |

|

|

|

Galvanized Sheet |

● |

● |

● |

● |

● |

|

|

|

|

Iron |

● |

● |

● |

● |

● |

● |

|

|

|

Mild Steel |

● |

● |

● |

● |

● |

● |

|

|

|

Aluminum |

● |

● |

● |

● |

|

|

|

|

|

Brass |

● |

● |

|

|

|

|

|

|

|

2000w Fiber Handheld Welding Penetration Thickness |

||||||||

|

Thickness |

1mm |

2mm |

3mm |

4mm |

5mm |

6mm |

8mm |

10mm |

|

Stainless Steel |

● |

● |

● |

● |

|

|

|

|

|

Galvanized Sheet |

● |

● |

● |

● |

|

|

|

|

|

Iron |

● |

● |

● |

● |

|

|

|

|

|

Mild Steel |

● |

● |

● |

● |

|

|

|

|

|

Aluminum |

● |

● |

● |

|

|

|

|

|

|

Brass |

● |

● |

|

|

|

|

|

|

Package and Shipment

|

Model |

Package Size |

Gross Weight |

|

BE-WF1500M |

Cantilever Arm: 1.64*1.1*0.6M Main Machine: 1.16*0.69*1.23M Working Table: 0.62*0.44*0.66M |

400KGS |

|

|

|

|

Inside layer is covered by thickening plastic film and fastened. |

Middle Layer wrapped by thick sponge foam to avoid shaking on the way. |

Outer layer packed by professional export thick wood craftcase. |

-

Vova Boyko

★★★★★Post a review on From Russia

Perfect welding seam, and much much better than traditional welding machine. Welding smoothly and firmly. We are building new factory and will add more units if working well.

-

Jose Hernandez

★★★★★Post a review on From US

Machine performs well. Very easy to use, and free of maintenance. Our workers are quite satisfied with the machine. Thank you BST Laser!

-

Stephanie Lunder

★★★★★Post a review on From Canada

Very professional. This machine can weld on different molds. It really beyond our expectation. No need after polishing and sanding.The machine so amazing!

-

Pramod Mahato

★★★★★Post a review on From Australia

We use the machine to weld injection mold. The welding speed very very fast. It can save 3 welders’ job and save us huge cost! Thanks for the new laser technology!

-

Ana Garcia

★★★★★Post a review on From Spain

We do a lot of study before purchasing. There are different choice on market with different offers. Never use such machine before, so at the beginning we are a little bit worried, but finally found out BST is very professional and provide excellent after-sale service. Be rest assured to buy!

-

Mohammed Makki

★★★★★Post a review on From UAE

It is definitely faster than argon welding. The welding seam is exquisite and bear more pressure. Workers feel relaxed!

-

choi yunje

★★★★★Post a review on From Korea

Machine is same as seller’s description. Easy to use, no need much skills. Workers can operate the machine after 30 minutes training. It is the right machine we require!