Auto Flange Channel Letter Bender Machine for Steel and Aluminum

| Category: | Channel Letter Bending Machine |

| Model No.: | BEL-X180 |

| Views: | 1500 |

| Rating: | ★★★★★4.8/5 Based on 1200 Votes |

| Price Range: | US$8000 – US$12000/set Based on the Features |

| Payment Term: | T/T Bank Transfer, Western Union, Paypal, Alibaba Trade Assurance |

| Leading Time: | 15-20 Days |

| Shipping: | Sea/Train/Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

The BEL-180X channel letter bender machine improved the auto notching and flanging model that was created using a conventional automatic super letter bending machine. It has all the features of model BEL-S150 as well as the ability to automatically notch and flange flat aluminum coils thanks to its multiple bending bar systems and quick-change bending mold system.

Which is the top-of-the-line bending equipment, especially appropriate for gigantic letters, stainless steel letters, punched letters, resin letters, enormous luminous letters, etc. (often found in squares and plazas). This machine can help save time and money, as it takes the manual labor out of creating custom channel letters. It is also easy to use and can be used to create a variety of custom designs.

Machine Feature:

- To eliminate material jams during processing, a material pre-straightening technology is used.

- Mechanical arm alternatively feeding structure ensures quick feeding speed and no material distortion

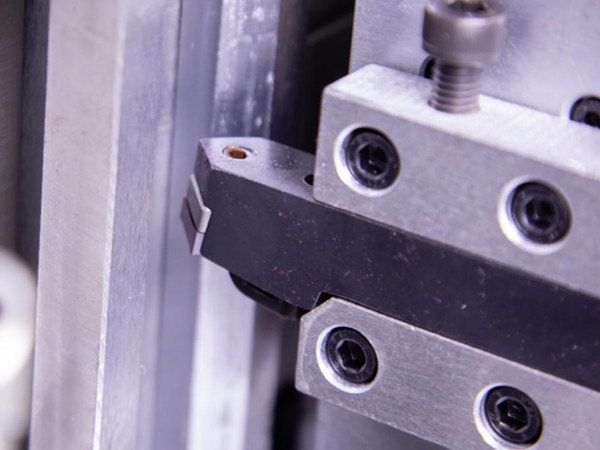

- Slotting tools are comprised of high-strength alloy blades that can notch coils up to 2mm (0.059″‘).

- Top China brand five-axis servo systems capable of v-cutting stainless steel and aluminum up to 1.5mm (0.059″).

- Automatic flanging to make channel letter clinching more versatile and simple.

- The telescopic bending blade and caster bending construction are long-lasting and precise.

- The electrical portion modularized, separated strong and weak circuitry sections, with no interference, more stable

- It is the most suitable model for producing trim cap channel letters, reverse channel letters, and flanged channel letters.

Parts Introduction

Seek for Efficiency

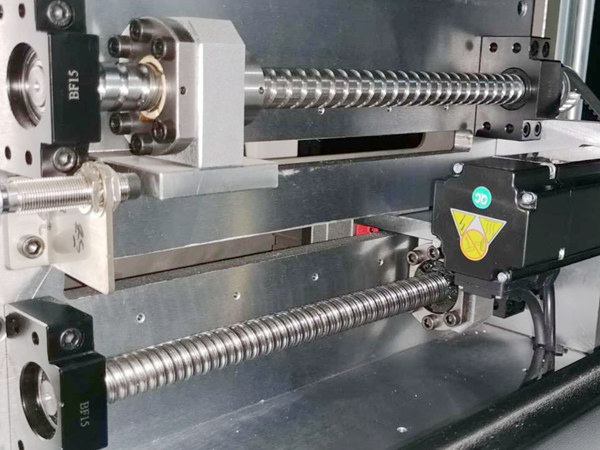

- Control of servo motors and ball screws, pneumatic clamping, and alternating feeding structure

- High-precision, rapid speed, and massive power.

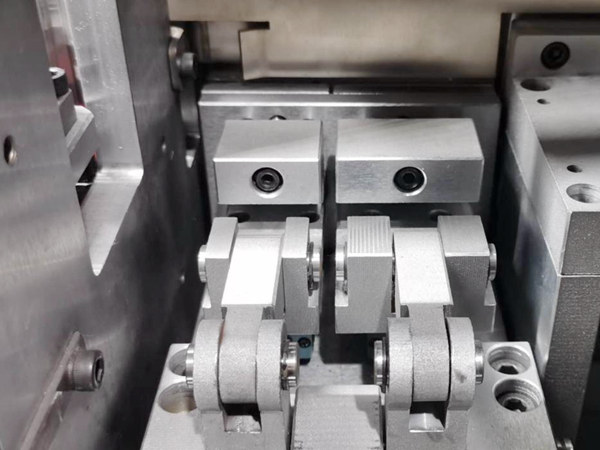

Alternate Clamping and Feeding with Grinding-grade Screw

- During high-speed running, it has improved precision and toughness.

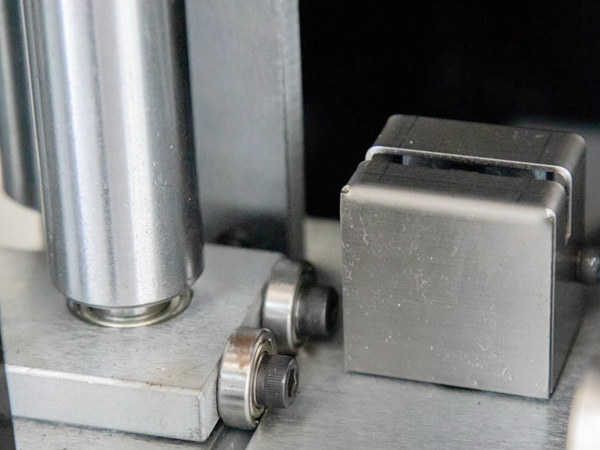

Closed-loop Feeding Test System and high-precision encoder

- Determine the length and speed of the feeding to prevent jamming.

Manipulator Fixture

- Emery spraying is being used to avoid feeding slippage.

- Ensure precise feeding and alleviate the issue of delayed processing efficiency caused by inaccurate feeding.

Unique Material Receiving Reminder Function

- It guarantees that the materials processed by the shearing machine are not wasted and that they are utilized more sensibly and effectively.

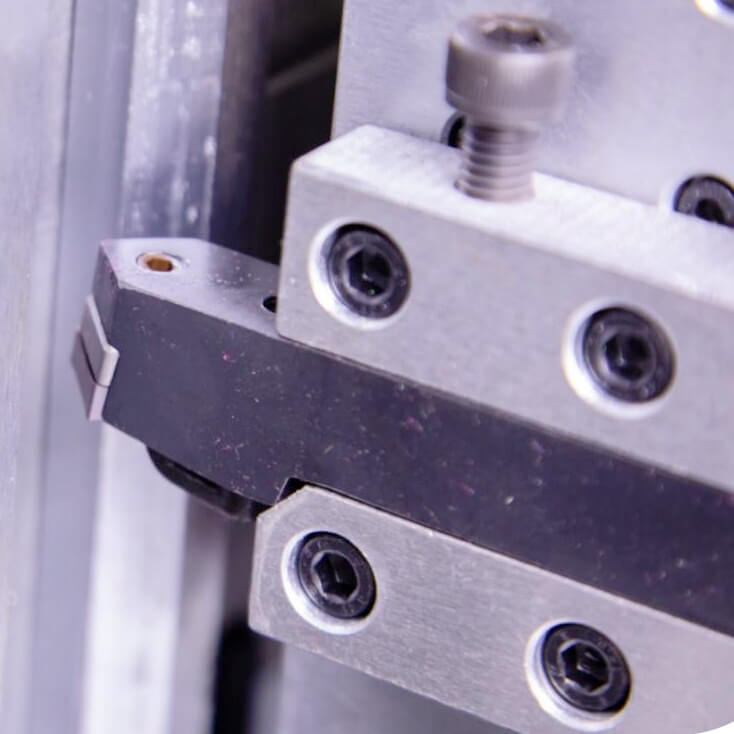

Korean Korloy hard alloy steel blades

- Double-sided octagonal, minimal cost of cutting, and simple to replace. There are no burrs in the cut.

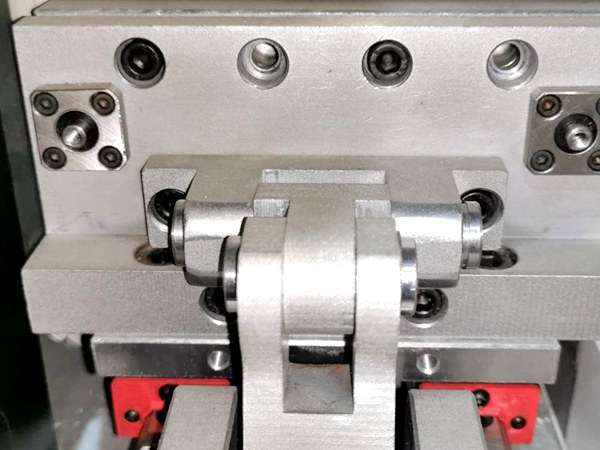

Circulated and Progressive Slotting Structure

- Use TBI ball screws for accurate and stable operation.

- Ensure even slotting depth and flawlessly finished letters.

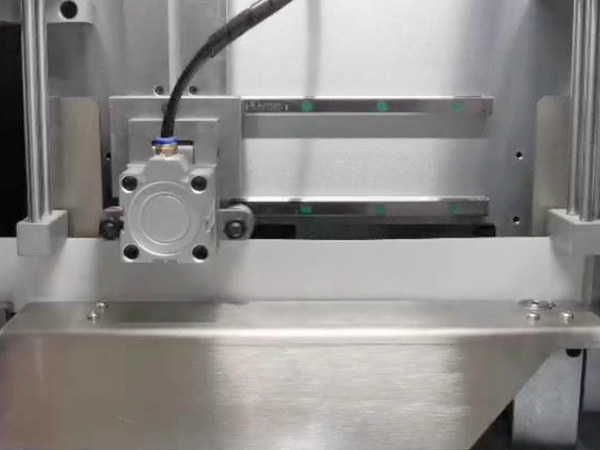

Pneumatic Slotting Control

- With its small and stable structure, high degree of modularity, and simple maintenance, it completes the shearing action.

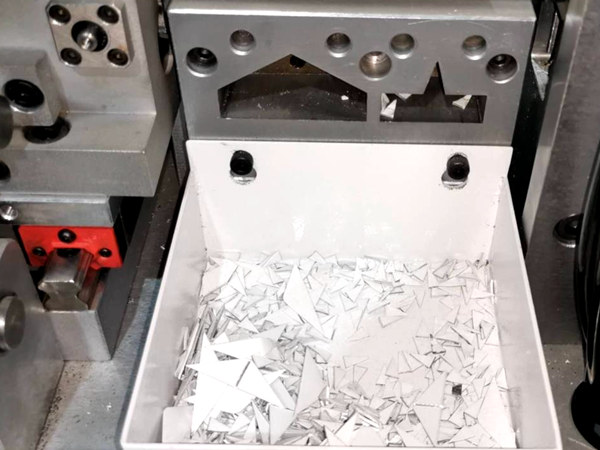

Built-in Waste Collection Box

- It effectively recovers trash while also keeping the equipment clean.

Right-angle Folding Structure

- The flat strip is folded utilizing a pneumatic right-angle folding structure, and all parts are CNC machined. With a high-strength structure that is simple to clean and maintain.

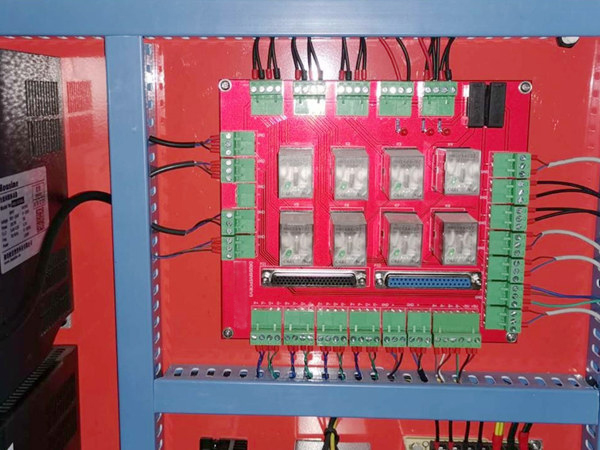

Integrated circuit board

- It makes the electrical component modular, with a clear layout and control classification. There is no interference since the circuit component is split into strong and weak.

High-quality Servo motors and drives

- They are reliable in operation and of high quality.

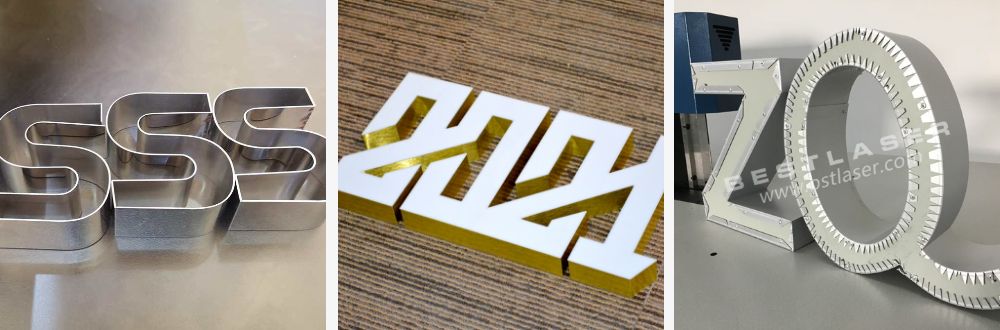

Application

Advertising channel letter notcher applications include logos, signs, neon signs, billboards, light box production, outdoor advertising, and other advertising channel letter production.

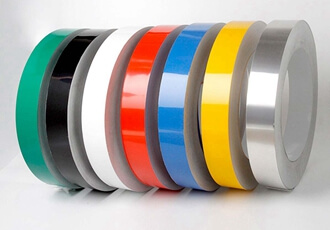

Aluminum strip bending, stainless steel strip bending, iron bending, galvanized steel bending, and galvanized pipe bending are all examples of applicable materials. (There are two types of slotting knives: one for bending aluminum and another for bending stainless steel, galvanized steel, and so on.)

Optional Items

| Category | Feeding system | Precision screw transmission and mechanical arm alternatively feeding structure (closed loop self-test system) |

| Slotting system | Hard alloy planer | |

| Notching structure | Notching by air cylinder | |

| Flanging structure | Pneumatic flanging by air cylinder | |

| Bending system | Double -pole alternate part-arc institution and patented alternative arc-extrusion structure | |

| Driving motor | Servo motor 3 set; stepper motor 1 set | |

| Weight | 800kg | |

| Dimensions | Body: L2140mm*W700mm*H1560mm; Feeding table: L500mm*W500mm*H1100mm | |

Performance |

Material category | Flat aluminum / Stainless steel / Galvanized plate (height: 20-180mm) |

| Material thickness | Flat aluminum: 0.6 – 1.5 mm/ SS: 0.3-1.2mm / Galvanized sheet: 0.4-1.2mm | |

| Flanging thickness | Flat aluminum 0.8mm | |

| Notching angle | 30°/ 120° | |

| Flanging width | 10mm | |

| Support format | AI / PLT / DXF / NC | |

| Feeding accuracy | Length + 0.1mm Radius > 4mm | |

Sfotware |

Control card | Leetro Four -axis motion control card |

| Software system | Auto drive / CBS4 auto bending system | |

| Input voltage | 220V 50Hz 3Kw | |

| Air pressure | ≥0.8Mpa |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-X180 | 250cm×82cm×170cm, 3.485CBM | 650KG |

|

|

|

| Inside layer is covered by thickening plastic film and fastened. | Middle Layer wrapped by thick sponge foam to avoid shaking on the way. | Outer layer packed by professional export thick wood craft case. |

-

Hossein Azimi

★★★★★Post a review on Aug 21, 2022 From UK

The machine is quite solid structurally and has very good, simple software and performance.

-

Muhammad Tayyab

★★★★★Post a review on Aug 21, 2022 From UK

It is a really powerful equipment that has attracted a lot of potential customers to my firm and comes highly recommended to those looking to enter the sign industry.

-

Ermal Alushi

★★★★★Post a review on Aug 21, 2022 From Italy

The trim cap channel letter bender machine BEL-A200 is operational, but we do not have technical help at this time.

-

Josef Helmlinger

★★★★★Post a review on Aug 21, 2022 From Chile

The machine works well. I will introduce to friends to buy.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From Spain

Your letter bending machine is very fine and I am so happy and thankful to u and ur company.

-

Fredy Lasso

★★★★★Post a review on Aug 21, 2022 From France

Also let you know, we have been using the machine very well, because of pandemic we haven’t been able to us it that much, but in the little we have made really good letters with it!

-

Ernesto Reyes

★★★★★Post a review on Aug 21, 2022 From USA

Excellent machine. I’d want to thank the supplier for her assistance and support during the purchase process.