Automatic Aluminum Frame Round Bending Making Machine For Light Box

| Category: | CNC Bending Machine |

| Model No.: | BEL-AK150 |

| Views: | 5000 |

| Rating: | 5/5 Based on 3000 Votes |

| Price Range: | $3,800-$4,500/set Based on the Features |

| Payment Term: | T/T Wire Transfer, Alibaba Trade Assurance,L/C |

| Leading Time: | 3-5 Working Days |

| Shipping: | Sea / Train / Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

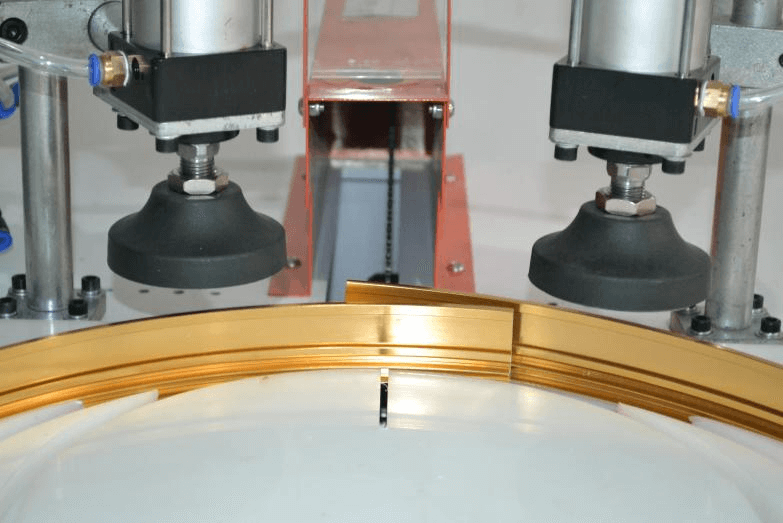

The single-side automatic aluminum frame bending machine is designed for forming simple-shaped mirror frames. The light box frame bender precisely bends aluminum profiles into the desired frame shape with high accuracy and stability, ensuring consistent dimensions and excellent appearance quality. Equipped with interchangeable molds, it supports various frame sizes and specifications.

Technical Feature

- Efficient Material Feeding

Equipped with a sturdy support frame and adjustable side baffles, the machine ensures smooth and accurate material feeding for different profile widths. - High-Precision Feeding System

Four servo-driven feed shafts with adjustable pressure deliver precise control for various material thicknesses, guaranteeing stable and accurate positioning. - Smart Bending Performance

Powered by a high-torque servo motor, the bending system precisely forms aluminum profiles into smooth curves with consistent quality. - Durable & Reliable Structure

Built with a heavy-duty welded steel frame and CNC-machined 20mm carbon steel base, the machine offers excellent rigidity, high efficiency, and long service life

Parts Introduction

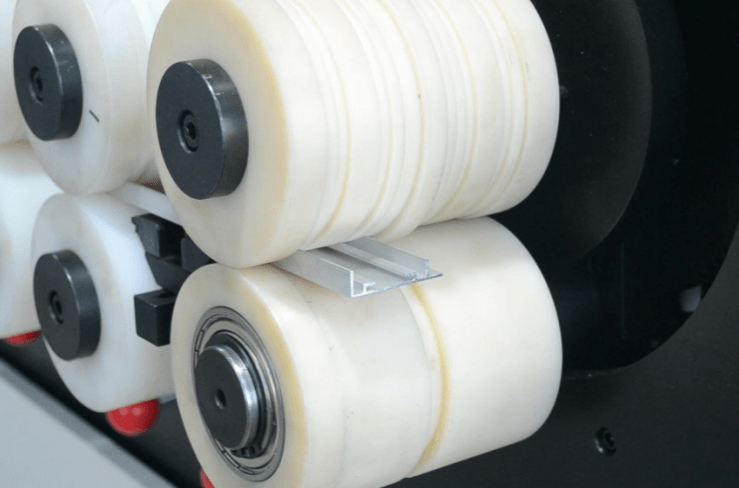

Pressure Regulation Structure

Can adapt to different materials feeding,Prevents material slippage to maintain feeding accuracy.

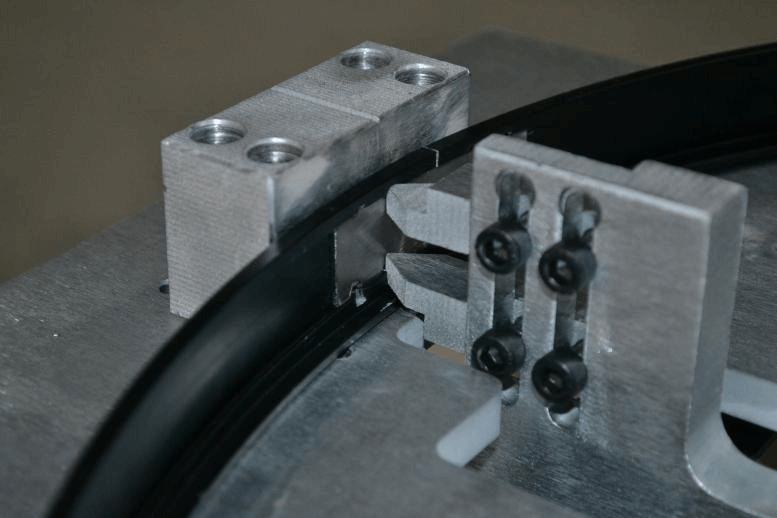

Material Return to Zero Switch

Adjustable position to accommodate different sizes of aluminum profiles,Uses slot type photoelectric switch which is more sensitive and accurate

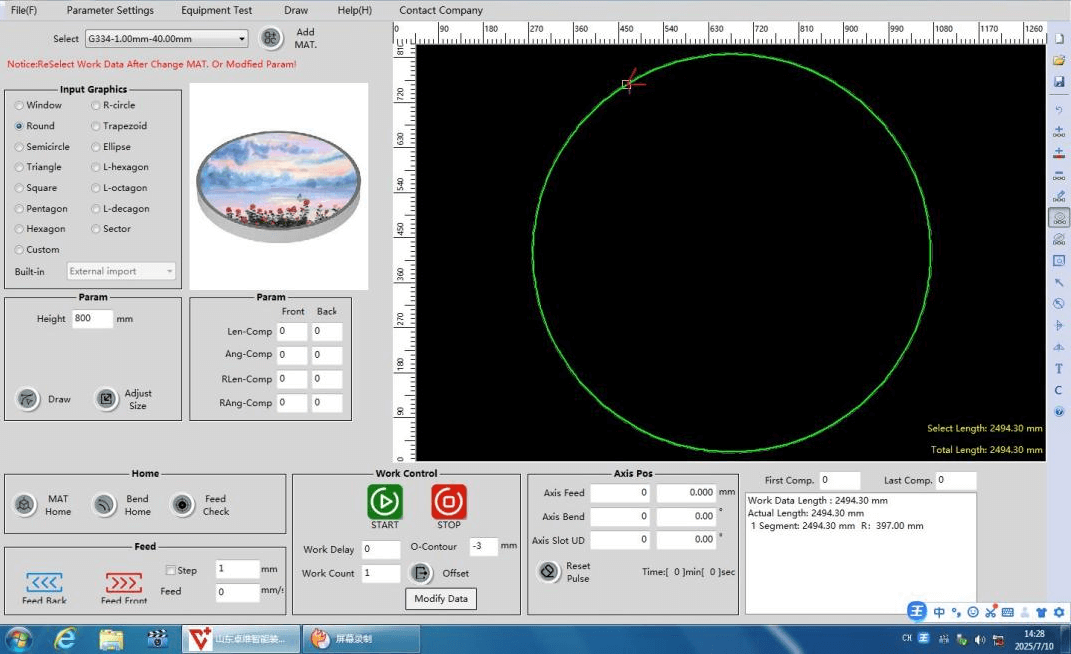

Direct and at-a-glance Control Software

Make sure machine operation is more convenient, simple and fast.Will help you to build your production line to a higher level.

The software has more than a dozen preset graphicsto meet the usual needs, but also can produce custom shapes

Bending System

Servo motor provide enough power to bend material,when machine is working,servo motor will turn to suitable angle,then machine will start to bend the curve of shape.

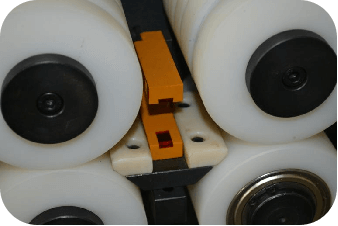

Feeding Structure

Feeding axis is made of five sets nylon, Gear drivers Rolling continuous feeding structure,fast speed,for example ,if we process a 400mm circle,it just spend 15 second.

Application

The Automatic Aluminum Frame Bending Machine is used for forming aluminum profiles into curved shapes for mirror frames, photo frames, LED light boxes, decorative trims, and architectural designs. It ensures high precision, smooth surface finish, and stable performance, making it ideal for both mass production and customized frame manufacturing.”

Optional Items

| Feed Speed | 150mm/s |

| Feed Accuracy | ±0.2mm |

| Bend Axis Torque | 200N·M |

| Die Axis Length | 120mm |

| Minimum Bend radius | 50mm |

| Control System | Self Developed Automatic bending system |

| Machine Size | L1302mm*W780mm*H1650mm |

| Power | 1.5KW |

| Voltage | 220V 50Hz 30A |

| Weight | 450Kg |

| Shape | Circle、ellipse、runway circle、polygon and irregular figure |

| Material | Aluminum profile、Stainless steel |

| Industry Application | Frame、mirror frame、Decorative picture、Ceiling、lamps and lanterns、Advertising、Furniture and metal forming industry |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-AK150 | L125Cm×W84Cm×H127Cm,1.333CBM | 450KG |

Package and Shipment

We have 3 layers package.

- Waterproof thickening plastic bag

- Foam to protect from shaking

- Non-fumigation wooden box which comply with export standard

|

|

|

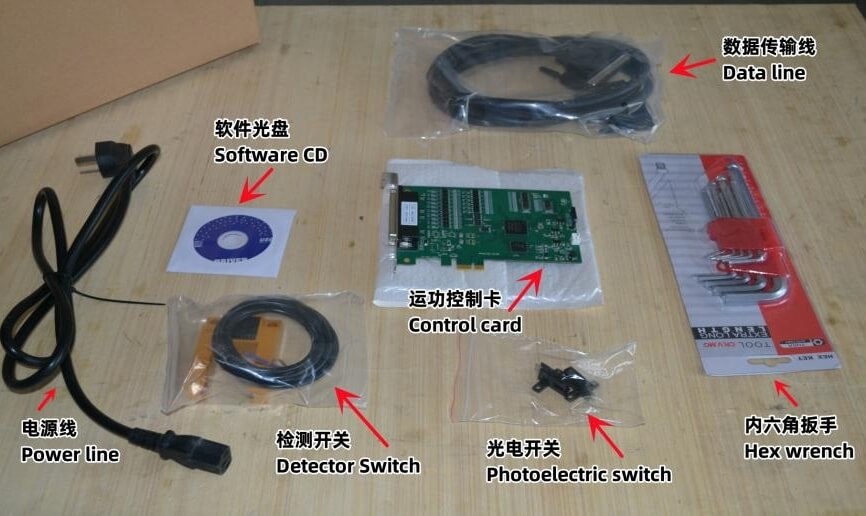

Free Spare Parts

-

David M.

★★★★Post a review on From United Kingdom

“The bending accuracy is outstanding. Every aluminum frame comes out perfectly shaped and consistent in size. This machine truly delivers industrial-level precision.”

-

Carlos R.

★★★★★Post a review on From Spain

“The operation is very simple and efficient. Our workers learned to use it in a short time, and it has greatly improved our production speed.”

-

Anna L.

★★★★★Post a review on From Germany

“The machine’s structure is solid and reliable. It runs smoothly with almost no vibration, ensuring excellent surface quality on every bend.”

-

Ahmed K.

★★★★★Post a review on From Egypt

“The after-sales support team is very professional and responsive. They provided detailed guidance during installation and quickly solved our technical questions.”

-

Michael T.

★★★★★Post a review on From USA

“Switching between different frame sizes is easy thanks to the adjustable molds. It’s a great solution for both small-batch and large-scale production.”

-

Kenji S.

★★★★★Post a review on From Japan

“The servo-driven control system ensures high precision and stability. We’ve been using it for over a year with consistent results and minimal maintenance.”