Fully Auto Light Box Mirror Photo Frame Aluminum Metal Bending Machine

| Category: | CNC Bending Machine |

| Model No.: | BEL-AD150 |

| Views: | 8000 |

| Rating: | 4.9/5 Based on 2000 Votes |

| Price Range: | $4,900-$5,500/set Based on the Features |

| Payment Term: | T/T Bank Transfer, Alibaba Trade Assurance,L/C |

| Leading Time: | 7-10 Working Days |

| Shipping: | Sea / Train / Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

The Fully Automatic Aluminum Bending Machine is a high-precision CNC profile bending solution designed for fabric light box frames, mirror frames, photo frames, and decorative aluminum structures.

This advanced light box frame bender integrates automatic feeding, measuring, and double side bending functions, delivering stable performance, smooth curves, and excellent repeatability.Powered by a high-torque servo motor and intelligent control software, it ensures efficient, accurate, and easy operation for various aluminum alloy profiles.

Technical Feature

- Powerful Servo Motor: High-torque servo motor ensures stable bending performance and effortlessly handles high-hardness materials.

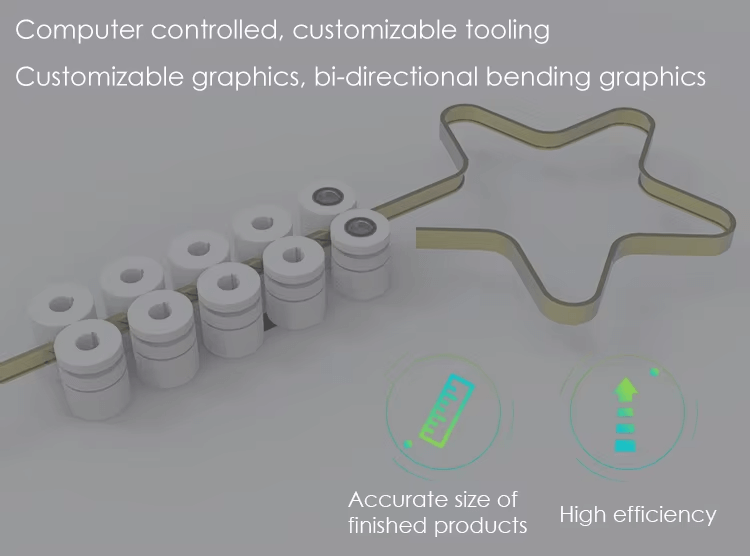

- Bi-directional Bending :Not only can bend the classic graphics like runway circle,square,oval ,etc but also can support complicated and irregular shapes .

- Closed-Loop Control System: Provides double machining accuracy and ensures consistent bending results.

- Precision Gear Transmission: Delivers smooth operation, low noise, and high load-bearing capacity.

- Dual Feeding Motors: Enables efficient processing of ultra-thick aluminum profiles.

- Replaceable Mold Shaft: Quick and easy mold changes save time and reduce downtime.

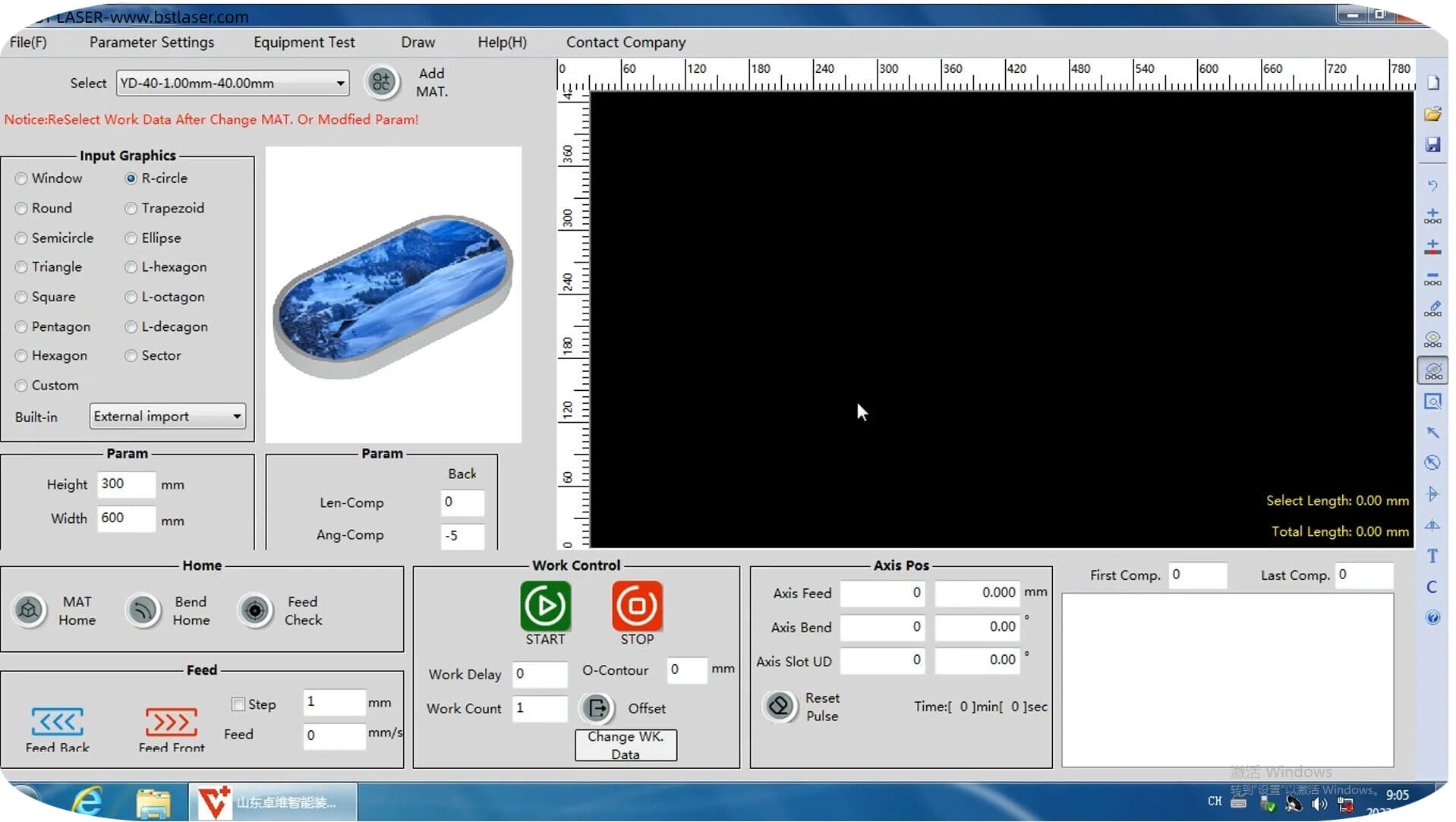

- User-Friendly Software: Simple to learn and operate, with intuitive control for rapid setup and high productivity.

- One-Click Software Upgrade: Supports online upgrades for zero-cost maintenance and continuous improvement.

- Robust Machine Structure: Built with precision structural components for durability, stability, and a clean industrial appearance.

Parts Introduction

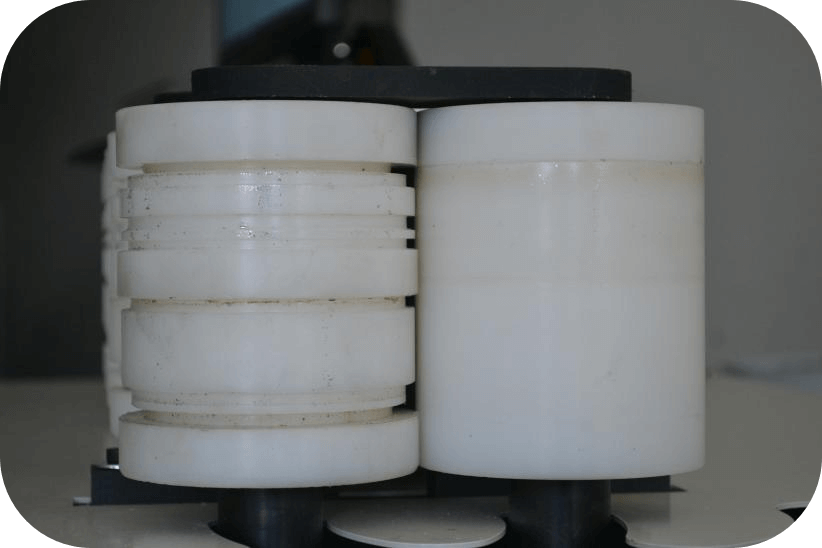

Advanced Feeding System

The machine features a continuous feeding mechanism with four nylon guide sets and precision gear drivers. It delivers high-speed, smooth material feeding—processing a 300mm circle in just 9.8 seconds.

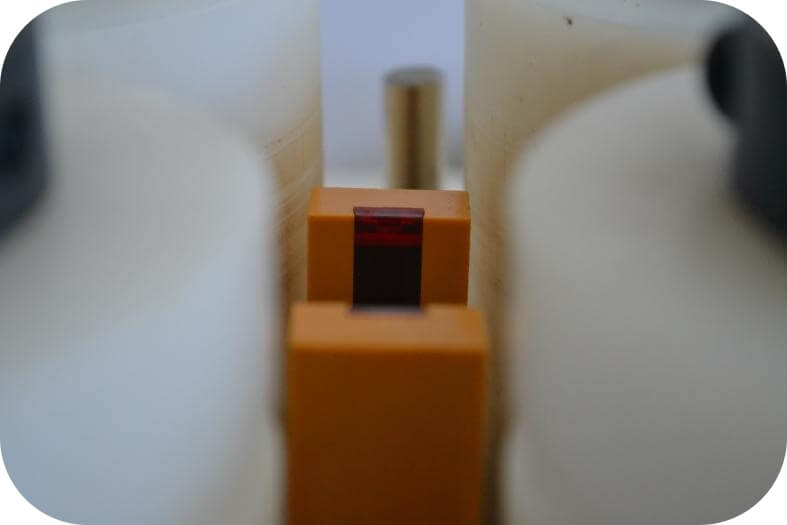

Material Detection Function

Equipped with a smart material sensor, the system alerts operators when the material is running low, ensuring uninterrupted production and preventing errors.

Precision Bending Structure

Powered by a high-torque servo motor, the machine adjusts automatically to the correct bending angle before forming curves. This guarantees consistent accuracy for various aluminum profiles.

Durable Machine Frame

The body combines 1.2mm sheet metal panels with a welded 2.0mm square tube frame and integrated pulleys for easy movement. Critical mechanical components are CNC-machined from 20mm carbon steel, ensuring high rigidity, transmission accuracy, and long service life.

One-Touch Operation

The updated one-button start and touch control interface simplify die changes, improve safety, and save valuable setup time.

Humanized CNC Controller

The advanced control software allows easy adjustment for different materials without repeated testing. It supports automated production line integration and improves overall productivity.

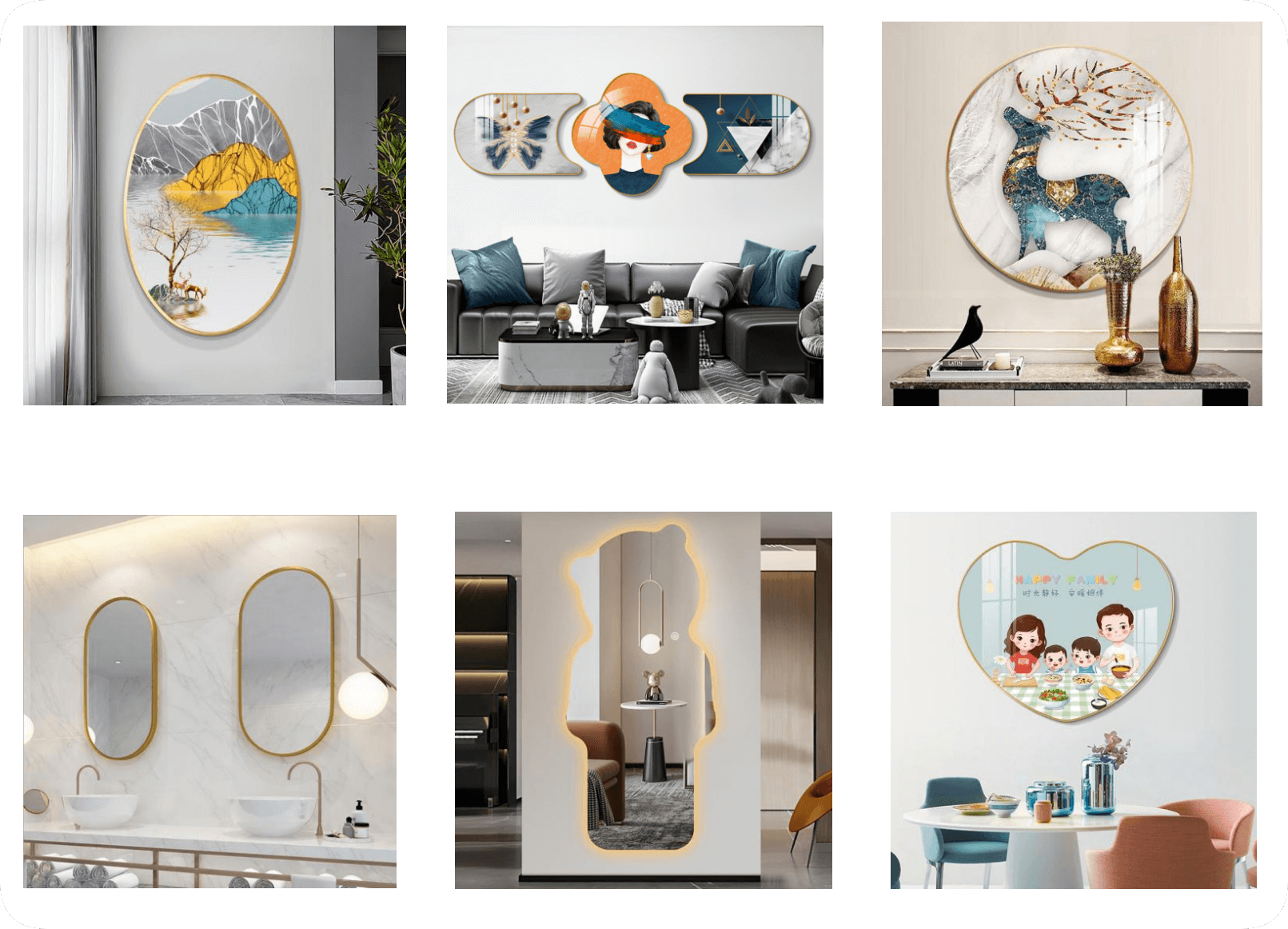

Application

This cnc profile bending machine machine is suitable for a wide range of industries and production fields, including:

- Fabric light box frame manufacturing

- Soft film light box frame production

- Mirror and picture frame fabrication

- Lighting frame and advertising structure processing

- Furniture metal edge and decorative aluminum frame bending

Bending Shapes :

Bending Shapes :

Available shapes :Circles, ellipses, runway circles, polygons,hearts, waves, pentagons, S-shapedand other bi-directional bending graphics,more able to customize the graphics.We can also customize the shapeof the cross-sectional structure of the material

Optional Items

| Feed Speed | 150mm/s |

| Feed Accuracy | ±0.1mm/m |

| Bend Axis Torque | 400N·M |

| Mold Shaft Length | 120mm |

| Min Bend radius | ≥50mm |

| Machine Size | L1100mm*W700mm*H1150mm |

| Package Size | L1250mm*W840mm*H1270mm |

| Machine Watt | 2.3KW |

| Voltage | 220VAC |

| Gross Weight | 400Kg |

| Shape | Circle、ellipse、runway circle、polygon and irregular figure |

| Material | Aluminum profile, Stainless steel,Copper,Iron |

| Industry Application | Frame mirror frame,Decorative picture,Ceiling,lamps and lanterns,Advertising.Furniture and metal forming industry |

| Voltage | 220V 50HZ (Can be customized) |

| Max Processing Thickness | 0.6~3.0mm |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-AD150 | L125Cm×W84Cm×H127Cm,1.333CBM | 400KG |

Package and Shipment

We have 3 layers package.

- Waterproof thickening plastic bag

- Foam to protect from shaking

- Non-fumigation wooden box which comply with export standard

|

|

|

-

John Müller

★★★★★Post a review on From Germany

“The CNC aluminum bending machine delivers perfect precision with every curve. Easy to operate and highly efficient — a great investment for our light box frame production line.”

-

Ahmed Youssef

★★★★★Post a review on From Egypt

“This machine handles thick aluminum profiles smoothly. The dual servo motors are powerful and stable. We’ve improved productivity by more than 30% since installation.”

-

Luis Fernández

★★★★★Post a review on From Spain

“Excellent performance and accuracy. The closed-loop control system really makes a difference in bending consistency. We’re very satisfied with both the machine and the support team.”

-

Rebecca Smith

★★★★★Post a review on From United Kingdom

“User-friendly software, fast setup, and reliable operation. The machine runs quietly and bends our advertising frames perfectly. Great value for money and great service!”

-

Kenji Tanaka

★★★★★Post a review on From Japan

“The automatic bending machine is compact, efficient, and precise. The software interface is intuitive, even for new operators. Perfect for mirror and picture frame production.”

-

Dmitry Ivanov

★★★★★Post a review on From Russia

“Strong structure and smooth gear transmission. We’ve been running it daily for months without issues. The after-sales service is professional and responsive.”

-

Michael Brown

★★★★★Post a review on From United States

“The servo system and mold replacement design save us so much time. Changing profiles is simple, and bending accuracy is outstanding. Highly recommend this model.”