Auto Hole Punch V-Notching Flanging 3D Channel Letter Bender

| Category: | channel letter bending machine |

| Model No.: | BEL-X180CUT-ATX |

| Views: | 6500 |

| Rating: | 4.9/5 Based on 1500 Votes |

| Price Range: | $12,000-$15,000/set Based on the Features |

| Payment Term: | T/T Bank Transfer, Alibaba Trade Assurance,L/C |

| Leading Time: | 15-20 Days |

| Shipping: | Sea / Train / Truck |

| Warranty Period: | Two Years with Lifelong Free Service |

- PRODUCT DETAILS

- TECHNICAL SPECIFICATIONS

- CUSTOMER TESTIMONIALS

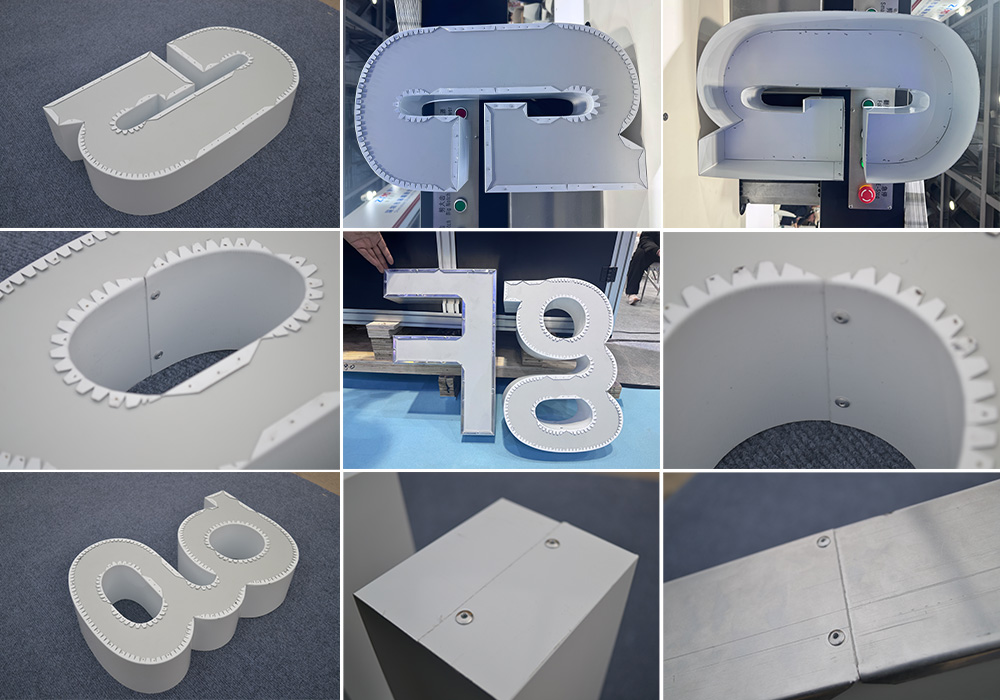

BST LASER New Launched Channel Letter Bender X180CUT-ATX is the perfect updating and optimization on model X180 CUT on machine’s mechanical structure ,bending accuracy and capacity.with additional featured auto hold punching function on the ending joint,help the users in completing the splicing process after letter processing in advance, saving processing time. Users do not need to manually punch again, improving 3d letter fabrication efficiency.

Technical Feature

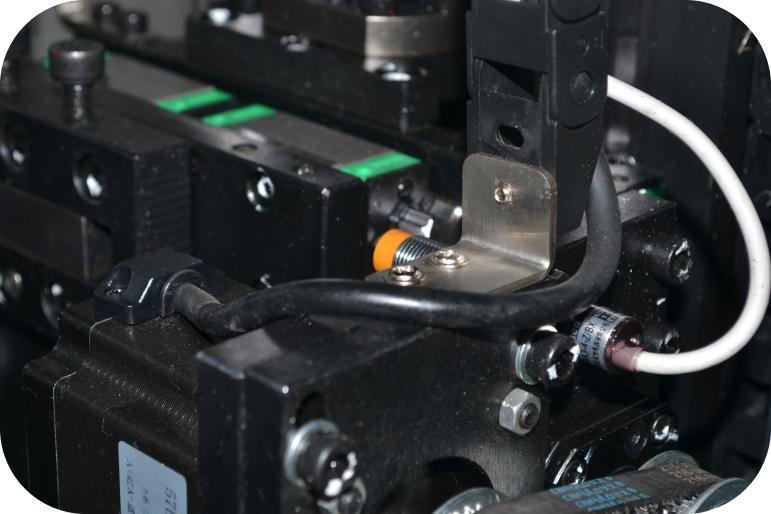

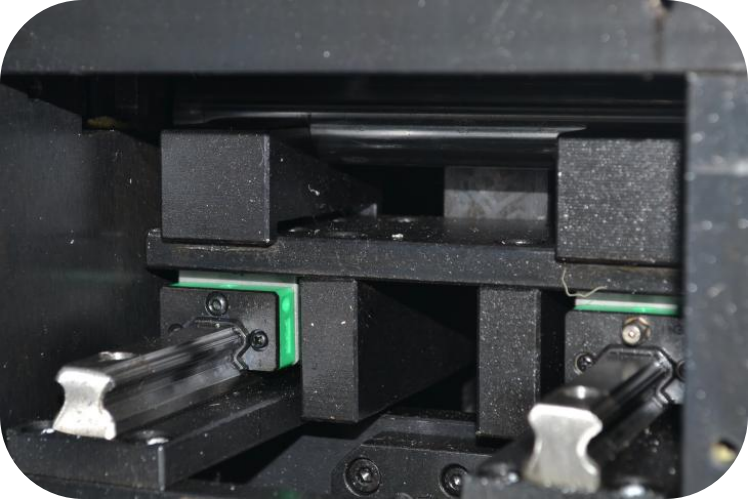

1. Enhanced Feeding Structure

The upgraded feeding system features a wider clamping range, providing better stability, especially for thicker materials that tend to shift or produce inaccurate lengths during bending. With improved clamping stability, the machine ensures higher precision in both feeding and bending operations.

2. Optimized Cutting and Bending Mechanisms

Significant improvements have been made to both the cutting and bending structures. The cutting height has been increased, and the arc bending performance has been significantly enhanced, resulting in more accurate and aesthetically refined letter shapes。

3. Integrated Punching Function & Improved Folding

A new punching function has been added to both the front and end of the material, allowing the finished letters to be used directly without secondary processing—greatly improving production efficiency. Additionally, the tooth-cutting and flanging mechanisms have been upgraded from pneumatic to servo-driven systems, offering greater precision and stronger letter structure.

4. Reinforced Machine Frame

The new machine shell is reinforced with 40 mm square tubes. Due to the overall weight of the machine, structural support is critical to prevent deformation during transportation or long-term use. The internal support frame ensures high load-bearing capacity and long-lasting durability.

5. Integrated Feeding Rack Design

The feeding rack is now integrated into the main machine structure, making the overall design more compact and stable.

This integration reduces the overall machine footprint and eliminates the need for a separate control cabinet, which also helps lower international shipping costs.

6. Transparent Observation Window & Modular Design

The front window is made of transparent glass, allowing users to clearly monitor the internal mechanical operations in real time.

Each functional module is housed in its own compartment, making it easy to access and service specific components in case of any issues—saving time and effort during.

Parts Introduction

Strong Machine Body with European Standard Design

Adopting 40 Square Tube as supporting frame and heavy cabinet which ensure machine’s loading capacity and non-deformation after long time running .

Material Flattening & Straightening structure

When flat aluminum coil is slight deformation,Operator can make material smooth and flat by adjusting this structure,it will make sure the feeding processing smooth.

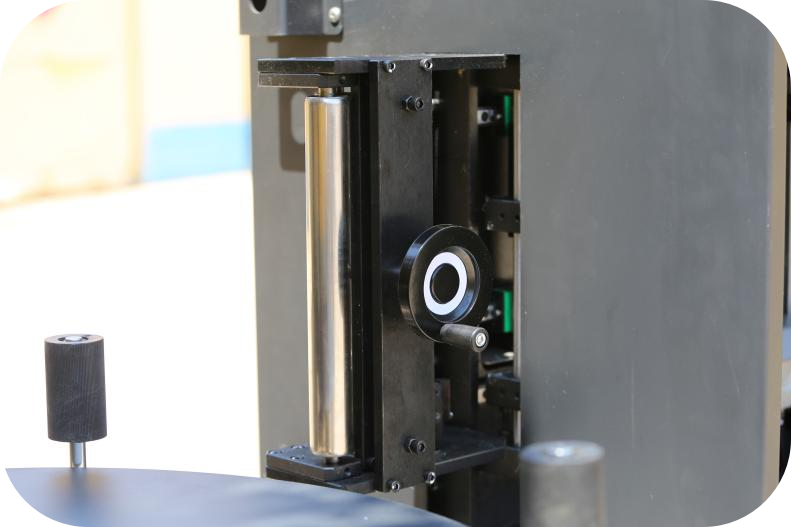

Mechanical Arm Alternatively Feeding Structure

With closed loop self-test system,The new design feeding structure is good at feeding thicken strips.

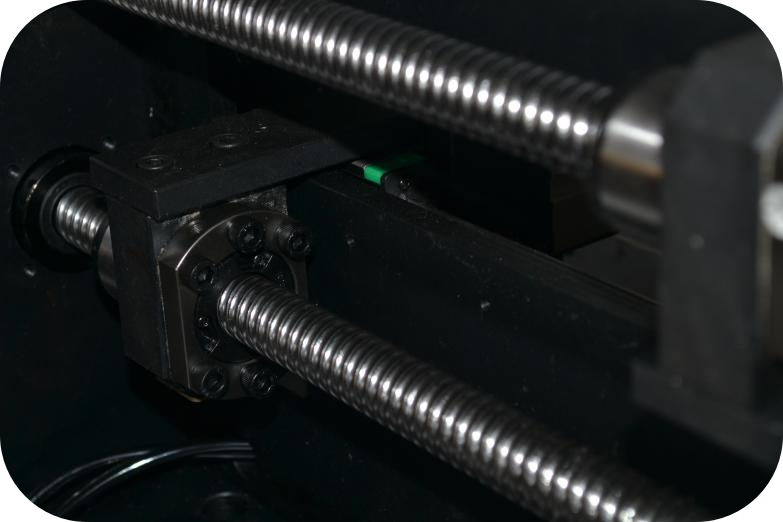

Ball Screw Feeding Structure

Higher precision,more stabilization.it will make sure that the length data of letter will be same as original size. so that the processed material can match with the back board well.

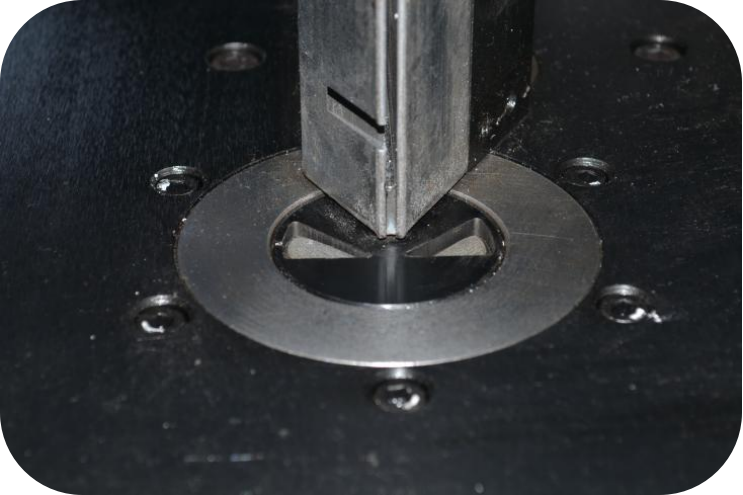

Circular Progressive Slotting Structure

It can ensure the depth of groove is same all the time when machine working,ideal for welding letter when the user need to make stainless steel strip with metal board together. the processed material will not be broken easily.

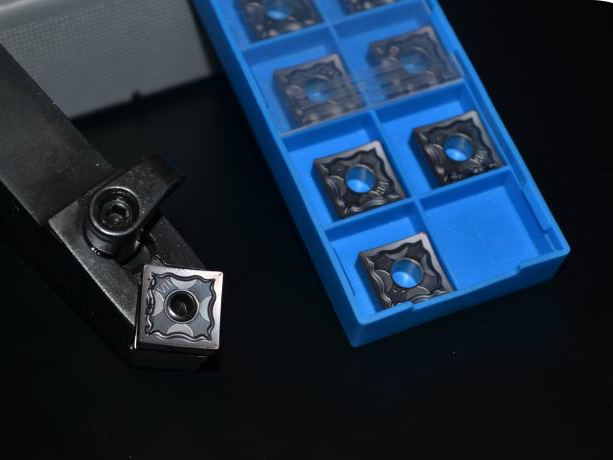

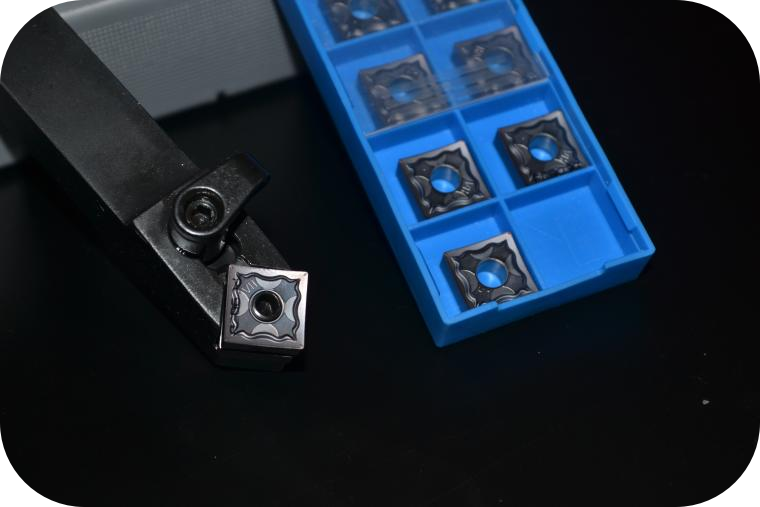

Korean KORLOY Slotting Knife

Planer tool can be used to process flat metal, such as stainless steel / galvanized sheet / Iron.replaceable blade ,one side have four tool noses,eight tool noses in total, lower use cost.

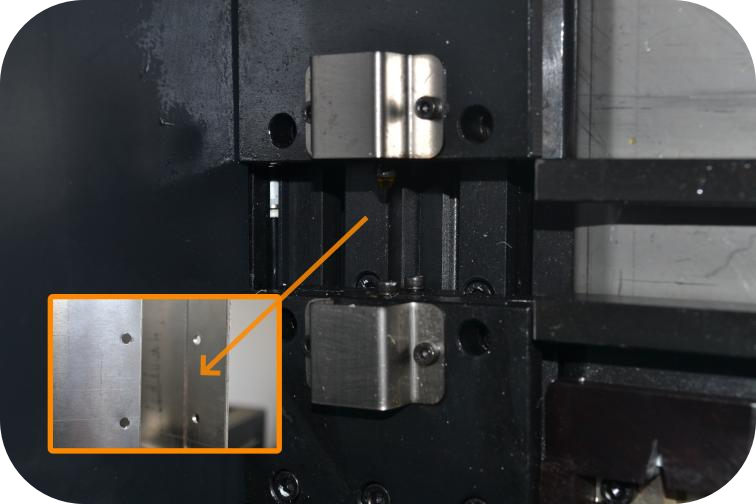

Punching Hole Structure

The punching function allows users to complete splicing preparation during letter processing, eliminating the need for manual punching and significantly improving efficiency.

Notching Structure

There two type of notching shapes (30°/ 120°)

it will be automatic chosen by software when machine process different letter file.

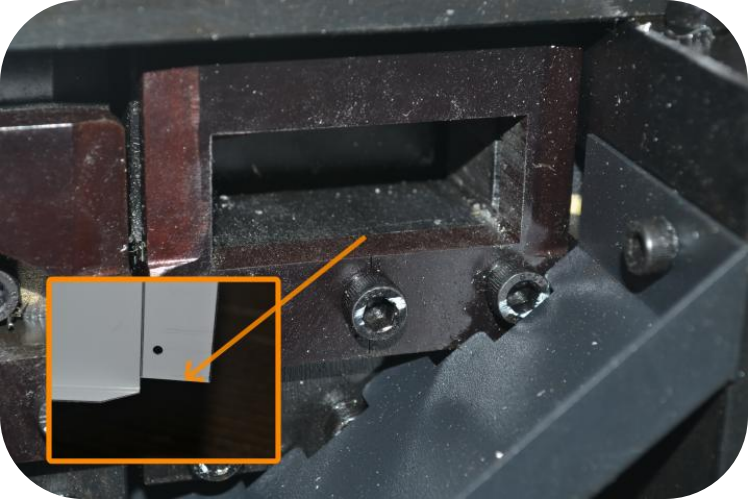

Trimming Structure

The reserved position cutting function avoids the back panel area of the letter shell at the start of cutting, improving the splicing quality of the first and last sections.

Flanging Structure

Ball screw drive flanging structure driven by servo motor.

It can fold 0.6-1.5mm flat aluminum coil and flange width is 10mm,simple machinery structure make sure that machine will run steadily.

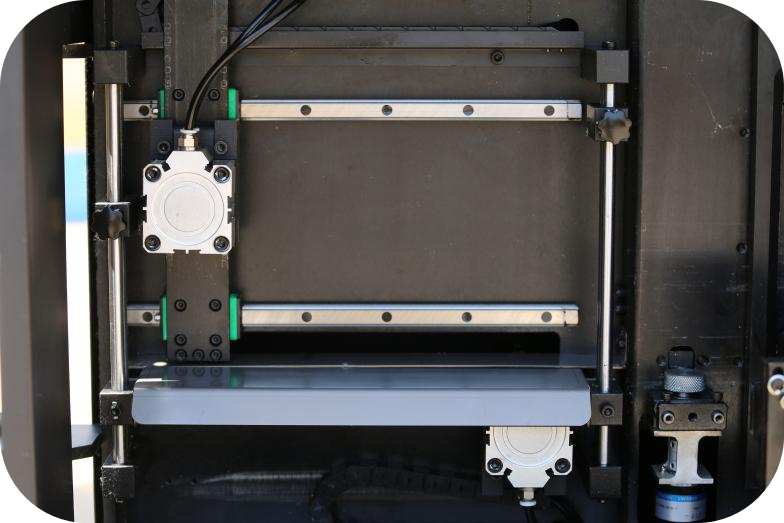

Bending Structure

Telescopic dual axis alternating bending structure.

More suitable for processing letters with small curvature in high precision.

High Quality Servo motor and Driver

It will make sure that machine can work well, servo motor will make bending structure more powerful, and machine will get high precision.

Waste Collection Box

Waste collection box, using a push-pull design scheme, easy to operate, and easier to clean the machine.

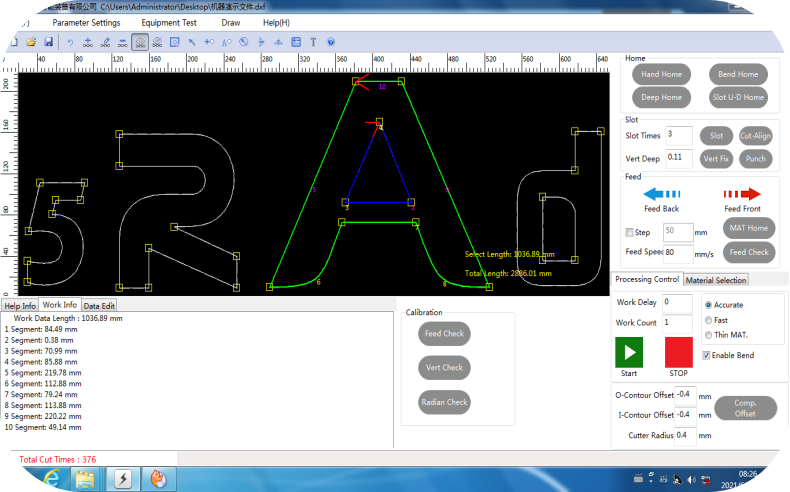

Advanced Bending Software

It is more suitable for user, Easy to operate, user friendly, easy to change parameters follow different material.

Application

BST LASER BEL-X180CUT V Notch Flange Channel Letter Bending Machine is the best channel bender machine for letters with v notch and flange of trim cap letters and back-lit reverse channel letters,specially for the high end market USA, Mexico, etc. With the advance holes punch function which can easily joint the finished ends together, save labor costs and improve work efficiency.

Optional Items

|

Hardware |

Feeding system |

Pneumatic clamping robotic arm alternating feeding structure |

|

Slotting system |

Hard alloy planer |

|

|

Notching structure |

Notching by Servo motor |

|

|

Punching structure |

Punching by Servo motor |

|

|

Trimming structure |

Trimming by Servo motor |

|

|

Flanging structure |

Flanging by Servo motor |

|

|

Bending system |

Telescopic dual axis alternating bending structure |

|

|

Driving motor |

Servo motor 7 set(Customized); stepper motor 1 set |

|

|

Weight |

680kg |

|

|

Dimensions |

L3100mm*W900mm*H1700mm |

|

|

Performance |

Material category |

Flat aluminum /Stainless steel / Galvanized plate (height: 40-180mm) |

|

Material thickness |

Flat aluminum:0.6 – 1.5 mm/ SS: 0.3-1.2mm / Galvanized sheet: 0.4-1.2mm |

|

|

Flanging thickness |

Flat aluminum 1.5 mm |

|

|

Notching angle |

30° / 120° |

|

|

Flanging width |

10mm |

|

|

Support format |

AI/PLT/DXF/NC |

|

|

Feeding accuracy |

Length + 0.1mm Radius > 4mm |

|

|

Software |

Control card |

Four -axis motion control card |

|

Software system |

Auto drive bending system |

|

|

Input voltage |

220V 50Hz 3.5Kw |

|

|

Air pressure |

0.8Mpa-1.2Mpa |

Package and Shipment

| Model | Package Size | Gross Weight |

|---|---|---|

| BEL-X180CUT-ATX | 190cm×82cm×168cm,2,719CBM | 650KG |

Package and Shipment

We have 3 layers package.

- Waterproof thickening plastic bag

- Foam to protect from shaking

- Non-fumigation wooden box which comply with export standard

|

|

|

-

James Anderson

★★★★★Post a review on From USA

This machine is very powerful, owing all the function that we bought from local American market but the price is only 1/10 , very cost-effective.

-

Michael Thompson

★★★★★Post a review on From USA

It’s with auto V notching and auto flange function, most importantly is with extra hole punch function, very useful and save our letter making time.

-

William Johnson

★★★★★Post a review on From USA

BST LASER offer very detailed technical instruction and training video, their technical support is great although we have around 12 hours different but they make it in on time service.

-

David Miller

★★★★★Post a review on From Puerto Rico

The machine works well, we’d like to introduce to friends who need them.

-

Matthew Clark

★★★★★Post a review on From Honduras

The channel letter bender is very fine and I am so happy and thankful to u and u company.

-

Kevin Roberts

★★★★★Post a review on From Canada

With strong package and good protection measures, machine arrived in good situation.

-

Miguel Munoz

★★★★★Post a review on From Mexico

High quality machine. I want to thank supplier for her support and enormous help during purchase.